Case Studies

Here you’ll find success stories and real-life applications where customers across various industries achieved exceptional results by harnessing the power of MFI equipment.

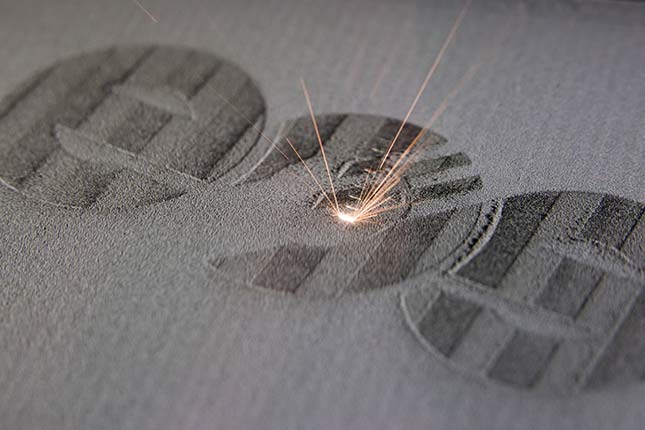

3D Logics: Mirror Finish

Client: 3D Logistics

Industry: 3D Printing

Featured Machine: HZ-40

Conn-Selmer: Sweet Music

Client: Conn-Selmer, Inc.

Industry: Musical Instrument Manufacturing

Featured Machine: HZ-330

Related Articles

Explore similar success stories and applications where MFI customers achieved exceptional results in their finishing processes.

How MFI Partner Roush Yates Engines Utilizes High-Energy Tumbling

https://youtu.be/Mo3AMNlcyBw

MFI Feature in Modern Machine Shop

High-Energy Barrel Finishers Efficiently Deburr Complex Parts Mass Finishing Inc. has developed high-energy barrel finishers that automate the process of deburring complex parts, saving time and eliminating the need to deburr parts by hand. ELI PLASKETT Associate...

The DeBertis Discover Barrel Polishing

The Twin Turbos found a turbo-charged way of polishing their billet aluminum car accessory parts. It’s increased speed and safety for their operation.

Knife Deburring and Polishing Made Easy

Knife deburring and polishing is a hands free operation in high-energy centrifugal barrel tumblers. Some customers are saving 8 hours of finishing time.