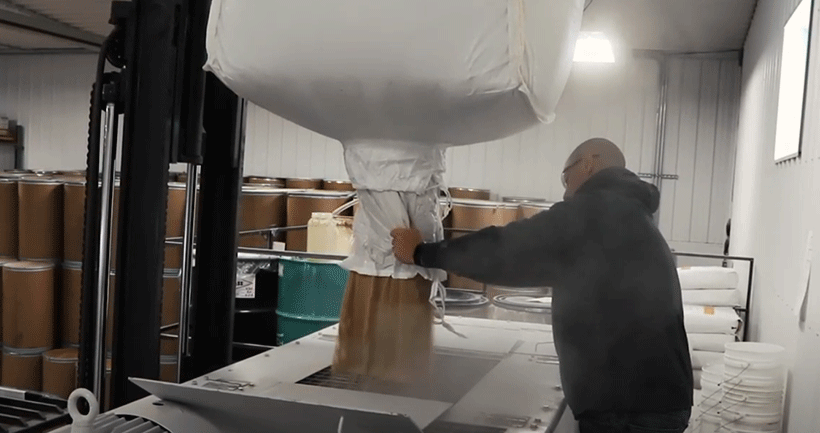

Mass Finishing, Inc. is known for our high-quality dry finishing media options. In corn cob media alone, MFI sells over 250 tons each year. At our 10,000 square foot media storage and production facility, we add a variety of oils, micro-abrasives, and polishing agents to this dry media and pack it into 50lb boxes and 250lb drums.

Since we started blending our own corn cob nearly two decades ago, MFI has made a few iterations and different blends for special applications. Many of our corn cob blends were based on our original MF-3 corn cob variety. Therefore, the previous names were variations of MF-3 name, including MF-3 Fat Free (a blend with no animal fat) and MF-3V (a blend for vibratory equipment).

To help alleviate confusion with our dry media varieties, we have designated these blends with their own number. Starting this year, we’re referring to our dry media according to the table below:

| MF-1 | Fat Free Corn Cob |

| MF-2 | Vibe Corn Cob |

| MF-3 | High-Energy Corn Cob |

| MF-5 | Cutting Corn Cob |

| MF-CW-1 | Corn Cob and Walnut Shell Mix |

| MF-WS-3 | Walnut Shell |

| Plain Cob | Plain Corn Cob |

About MFI Dry Media Varieties

MF-1: Fat Free Corn Cob

This treated corn cob variety was developed for those in the medical device field. Where we traditionally used stearic acid as a polishing agent, this variety uses a vegetable-based substitute to remove potential contamination with animal fat. Some refer to this variety as our “vegan cob.”

MF-2: Vibe Corn Cob

The original MF-3 blend of corn cob is well known in the surface finishing world as capable of producing incredible polishing results on parts. While it works great in MFI High Energy tumblers, it didn’t give great results in traditional vibratory polishing machines. This led to the development of a special treated corn cob that pulled back on some of the ingredients we use to mitigate heat.

MF-3: High-Energy Corn Cob

This is by far our most popular treated corn cob blend and our best-seller for high-energy polishing. We have tweaked the recipe over the years to help yield the best results and squeeze the most life we can out of the media. We use a proprietary blend of oils, pastes, and polishing agents to produce a brilliant shine on metallic and non-metallic parts.

MF-5: Cutting Corn Cob

This corn cob blend packs a punch! It is intended for dry finishing of parts while providing light deburring or edge break. It won’t take off stubborn burrs or round edges, but it does have a slight cutting effect that makes it more aggressive than our other blends without requiring water.

MF-CW-1: Corn Cob and Walnut Shell Mix

This corn cob and walnut shell mix was developed for a customer who produces high volumes of brass pieces. We’ve also had success with this blend on some of the more exotic metals such as nitinol and Inconel.

All of these treatments can be blended into fine grain or medium-grain corncob. We have also developed specialty blends and different mesh sizes upon customer request.

For more information and pricing, you can always reach out to us at sales@massfin.com. You can also order directly on our online store at www.massfin.com/shop.