The dental industry continues to evolve rapidly, with advancements like 3D printing enabling labs to produce precise, customized parts faster than ever before. At Mass Finishing Inc. (MFI), we specialize in high-energy finishing solutions that help dental labs achieve superior results while streamlining their processes.

This February, we’re excited to showcase our cutting-edge HZ-12 centrifugal barrel tumbling machine at the 40th Annual LAB DAY Chicago. Visit us to see how equipment can revolutionize your dental lab operations.

Meeting the Unique Needs of the Dental Industry

Dental labs are at the forefront of innovation, producing intricate parts like crowns, clear aligners, and implants using technologies such as 3D printing. However, while these technologies excel at precision, they require effective post-processing to deliver finished products that meet industry standards.

Simplifying Post-Processing with High-Energy Finishing

MFI’s HZ-Series Centrifugal Barrel Finishing Machines are designed to tackle the specific challenges dental labs face. Our machines excel at:

- Polishing and smoothing dental parts

- Cleaning support material from 3D-printed models

- Deburring sharp edges on aligners and other components

By automating these processes, our equipment can help reduce manual labor and free up technicians to focus on other priorities, improve part consistency, and enable labs to scale their operations efficiently.

Finishing Solutions for Metal and Non-Metal Dental Materials

Dental labs handle a diverse range of materials, each requiring specialized finishing techniques. MFI’s HZ-Series machines handle both metal and non-metal components with ease.

- Metal parts, such as cobalt chrome crowns and orthodontic brackets, benefit from precise deburring and polishing, ensuring a smooth, mirror-like finish.

- For non-metal parts like clear aligners and 3D-printed tooth models, the HZ-Series excels at removing sharp edges and cleaning residual support materials, delivering flawless results.

By offering versatility and consistent performance, our finishing machines help dental labs maintain high standards across all materials.

Clear Aligners Market

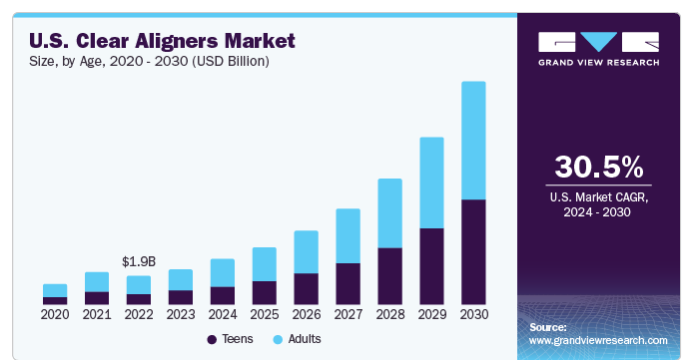

Clear aligners have revolutionized orthodontics, providing patients with a discreet and convenient alternative to traditional braces. With demand steadily rising, the global clear aligners market is projected to grow from $4.6 billion in 2024 to $9.25 billion by 2029, at a compound annual growth rate (CAGR) of 15% (source). Another report from Grand View Research highlights a 30.7% CAGR from 2024 to 2030 (source).

As dental labs face increasing pressure to meet this demand, production and finishing challenges become more pronounced.

Crafting clear aligners involves meticulous finishing steps such as trimming, polishing, and smoothing edges. Improperly finished aligners not only risk patient discomfort but also undermine the overall quality of the product.

Streamlining Clear Aligner Production

MFI’s HZ-Series machines offer a streamlined solution, addressing the specific finishing needs of clear aligner production by:

- Efficient Edge Removal: Removing sharp edges left after trimming to ensure smooth, patient-friendly aligners.

- Consistent Polishing: Achieving polished surfaces that improve comfort and enhance product quality.

- Batch Processing: Completing multiple aligners in a single 15-minute cycle to keep up with high-volume demands.

By automating these critical steps, the HZ-Series reduces manual labor, boosts productivity, and ensures dental labs can deliver high-quality aligners on time. With these machines, labs can confidently scale production without compromising on precision or patient satisfaction.

How the HZ-Series Works

The HZ-Series utilizes centrifugal force to deliver high-energy finishing. It is the fastest and most economical tumble finishing solution available.

The HZ-Series machines work by loading parts, finishing media, water, and compounds into barrels, which are then rotated in a planetary motion. This motion generates consistent contact between the parts and media, smoothing rough edges, polishing surfaces, and removing support material efficiently. By creating a multidirectional force, the HZ-Series achieves isotropic finishes that are uniform and precise.

This process saves time and delivers consistent results, making it an indispensable tool for dental labs aiming to increase productivity without sacrificing quality.

Choosing the Right HZ-Series Machine for Your Dental Lab

MFI’s HZ-Series offers options tailored to labs of all sizes. Three of the most common sizes used in the dental industry are the HZ-12, HZ-40, and HZ-60.

HZ-12

The HZ-12 is a favorite among dental labs for its compact design and powerful performance. Recent upgrades have enhanced its functionality, including toolless lockdown bars for faster setup and an improved stand design for safer mobility. These enhancements make the HZ-12 an even better fit for small-to-medium-sized labs.

HZ-40

While larger in size, the HZ-40 offers versatility for a wide range of applications. For high-volume operations.

HZ-60

The HZ-60 provides the capacity and efficiency needed to tackle larger production demands.

With these options, dental labs can select a machine that meets their specific needs while ensuring consistent, high-quality results.

Visit Us at LAB DAY Chicago 2025

Event Details

Mass Finishing Inc. will be at LAB DAY Chicago, the largest dental laboratory show in the world:

- Dates: February 20-22, 2025

- Location: Hyatt Regency Chicago, 151 East Wacker, Chicago, IL

What to Expect

See live demonstrations of the HZ-12, meet our finishing experts to explore solutions tailored to your lab’s needs, and discover how MFI can enhance your lab’s efficiency and quality.

Transform Your Lab with MFI

Ready to optimize your lab’s operations? Visit us at LAB DAY Chicago 2025 or explore our Dental Industry page to learn more about our innovative finishing solutions. Together, we’ll help you achieve exceptional results while reducing costs and improving efficiency.