Industrial Equipment & Metal Fabrication

Mass Finishing Solutions for Industrial Equipment Manufacturers and Metal Fabricators

Mass Finishing Inc. (MFI) has been providing high-quality parts finishing, deburring, and polishing equipment for over two decades. Whether you are working on large-scale industrial equipment or small precision parts, our HZ-Series High-Energy Centrifugal Barrel Finishing Equipment is designed to handle a wide range of sizes and complexities. We understand the importance of consistency and precision in your manufacturing processes, and our solutions are built to deliver just that.

MFI’s HZ-Series machines excel in evenly finishing, stress relieving, and removing burrs and defects on both small and large parts. They are the fastest and most economical form of finishing equipment available, helping operators finish their parts in a fraction of the time it would take using traditional finishing methods.

Common Parts:

Brackets

Tooling

Extrusions

Bearings

Sprockets

Ready to Send Your Sample Parts?

Running samples in our lab is the best first step in determining the right equipment and process for your part. We process most samples within a week, depending on the number of samples we’re currently working on.

Elevate Your Results with High-Energy Finishing

At Mass Finishing Inc., we understand the unique requirements of industrial equipment manufacturers and metal fabricators. Achieving a high-quality surface finish is crucial for ensuring the performance and durability of your products. With our comprehensive range of finishing, polishing, and deburring solutions designed specifically for your industry, you can expect the following benefits, and more when utilizing our HZ-Series Centrifugal Barrel Finishing Machines.

Benefits

-

Reduced labor costs and production time: Our innovative equipment streamlines the finishing process, helping you save time and resources.

-

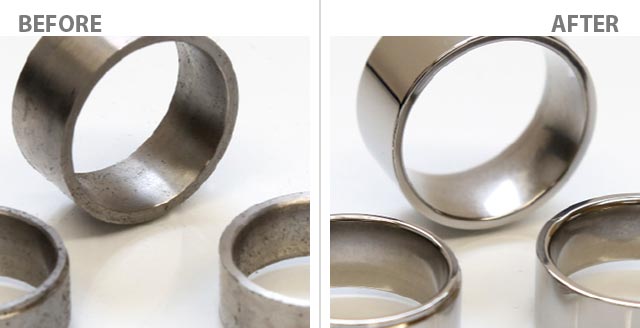

Consistent isotropic finish: We offer a quick and consistent isotropic finish, ensuring that your parts perform at their best.

-

Stress relief: Our machines are designed to stress relieve parts, enhancing their structural integrity and longevity.

-

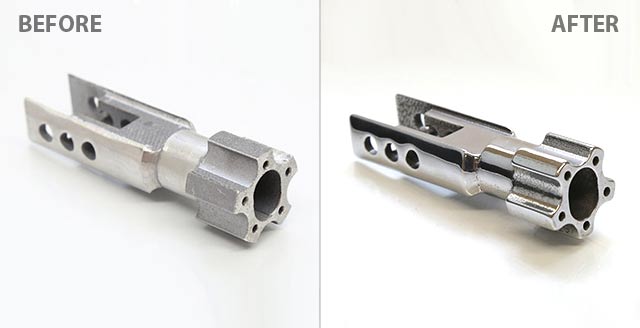

Removal of tough burrs and sharp edges: Our equipment effectively eliminates tough burrs and break sharp edges, resulting in smoother and more consistent finishes.

-

Mirror-like polish: Achieve a flawless mirror-like polish on your parts in a fraction of the time of other finishing methods.

Popular Equipment for Industrial Equipment Manufacturers & Metal Fabricators

The following model tends to be the most popular choice for those finishing industrial equipment or metal parts. The right model for your application will depend upon your specific part size, your production volume, and your finishing requirements. A full list of available equipment can be found on the equipment page.

HZ-60

Full-size machine for large production volume and part sizes.

Machine Type: High Efficiency

Max Part Size: 24″ L x 5.5″ D

Barrel Dimensions: 25.75″ L x 6″ D

HZ-220

Full size machine with long barrels and larger diameter.

Machine Type: Full Size

Max Part Size: 26″ L x 11″ D

Barrel Dimensions: 27.5″ L x 12″ D

Not sure what HZ-Series is right for you? You can view our Max Part Size Chart to see what model is best equipped to handle your part size and production volume.

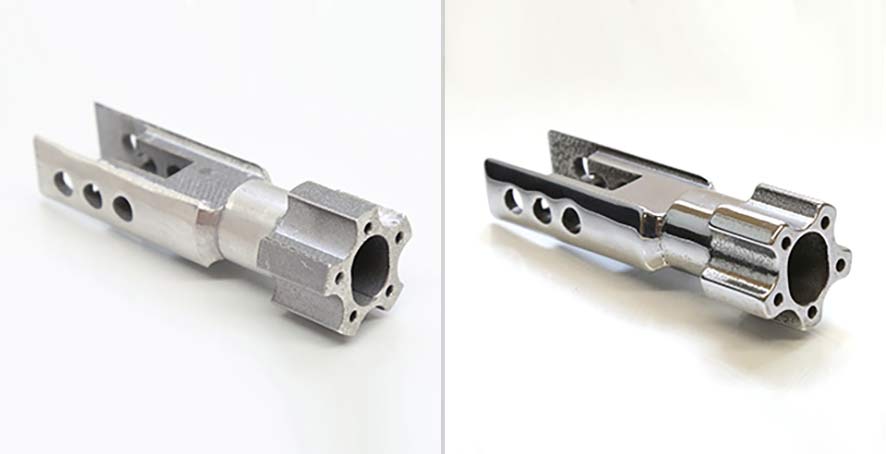

Industrial Equipment & Metal Fabrication Sample Parts

Common Materials: Heat-Treated Steel, Aluminum, Stainless Steel, Tool Steel, Hardened Steel, Carbon Steel

Enhance Your Mass Finishing Process with the Right Media Selection

Media is an essential component in the finishing process and is required for the proper operation of any Mass Finishing equipment. Finishing media is carefully selected based on its composition, shape, size, and performance to optimize the efficiency and effectiveness of the finishing process.

In addition to the wide variety of media and liquid and powder compounds in our Media Store, we also manufacture our own corn cob blends at our manufacturing facility in Howard Lake, MN.

For Industrial Equipment & Metal Fabrication Finishing