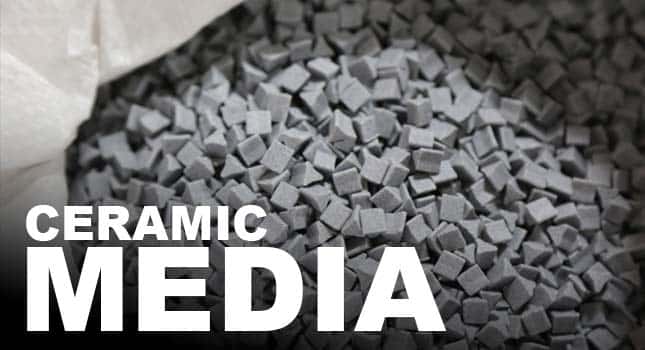

Ceramic Media

Ceramic Finishing Media

Ceramic media is a highly effective abrasive media commonly used in the initial stages of the finishing process for heavy deburring and grinding on harder ferrous metals. It offers exceptional cutting power and comes in a wide spectrum of shapes to suit various applications.

Common Uses: Cut/Deburr

Benefits of Using Ceramic Media

Ceramic media has superior cutting ability, efficiently removing burrs and imperfections, resulting in a smooth and clean surface. Ceramic media also offers excellent wear resistance, allowing for longer usage and reduced replacement frequency. This durability ensures consistent performance and cost-effectiveness.

Diverse Selection of Ceramic Media

Mass Finishing offers a comprehensive range of ceramic tumbling media in a wide variety of shapes, and sizes, providing a variety of finishing options. Choosing the right size and shape is essential, especially when working with parts with small openings to prevent media from getting lodged. MFI’s selection of ceramic media includes eight distinct shapes designed to cater to specific application needs. MFI provides the following ceramic media shapes; cone, triangle, cylinder, pin, ellipse, sphere, star, and tri-star.

MFI’s selection of ceramic media is made up of one of the following compositions:

1. Dura 30 Media: This composition contains a fine grain aluminum oxide baked into the ceramic shape. It provides a smooth finish while allowing for fast metal removal with medium wear. Dura 30 is particularly effective for achieving fine finishes on softer metals like aluminum, copper, and brass.

2. C-Bond: Featuring a coarser grain aluminum oxide, C-Bond offers an excellent cut to wear ratio, making it highly efficient for various applications. This general-purpose media can be used on both ferrous and non-ferrous metals, ensuring versatility and consistent results.

3. AH-41: AH-41 is an aggressive and high-density ceramic media known for its exceptional durability and fracture resistance. It is specifically recommended for heavy deburring operations where robust performance is required.

Ceramic Cone

Ceramic Triangle

Ceramic Fast Cut Triangle

Ceramic Cylinder

Ceramic Fast Cut Pin

Ceramic Ellipse

Ceramic Fast Cut Sphere

Ceramic Star

Ceramic Tri-Star