Plastic Media

Plastic Finishing Media

Plastic media is a versatile and efficient option used in both the first and second stages of the finishing process, particularly on softer non-ferrous metals. With the ability to produce an edge radius and prepare the part’s surface for plating, anodizing, or polishing, plastic media offers a range of benefits for achieving desired finishes.

Common Uses: Cut/Pre-Polish

Benefits of Using Plastic Media

One of the key advantages of plastic media is its lighter weight compared to ceramic or porcelain media. This makes it particularly well-suited for finishing softer metals like aluminum or acrylics, where a delicate touch is required.

Plastic media excels in general metal removal and pre-polishing tasks. Its fast and heavy cutting capability ensures efficient material removal while maintaining control over the desired surface finish. Plastic media is compatible with wet processing, making it highly effective when used with a tumbling soap like our MFI TS Compound.

Diverse Selection of Plastic Media

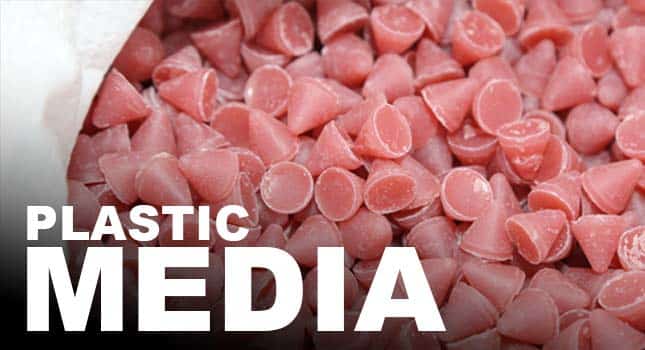

Mass Finishing offers a comprehensive range of plastic tumbling media in a wide variety of shapes, and sizes, providing a variety of finishing options. Choosing the right size and shape is essential, especially when working with parts with small openings to prevent media from getting lodged. MFI’s selection of plastic media includes four distinct shapes designed to cater to specific application needs including, plastic tetrahedron media, plastic cone media, plastic pyramid media, and plastic triangle media.

Plastic Tetrahedron

Plastic Cone

Plastic Pyramid