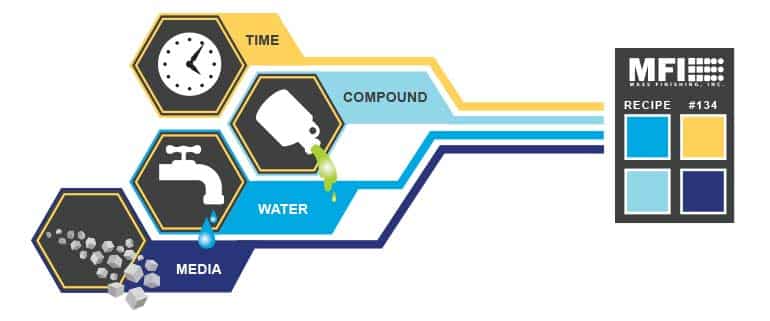

Believe it or not, the right mix of part finishing media is quite similar to the process of baking a cake – add a little bit too much of one ingredient, and the whole mix can change the outcome of your product – and, unfortunately, often ends badly with unwanted results.

To avoid such outcomes, MFI will guide you every step of the way to ensure that you get the perfect media mix tailored to your applications and desired surface finishing requirements.

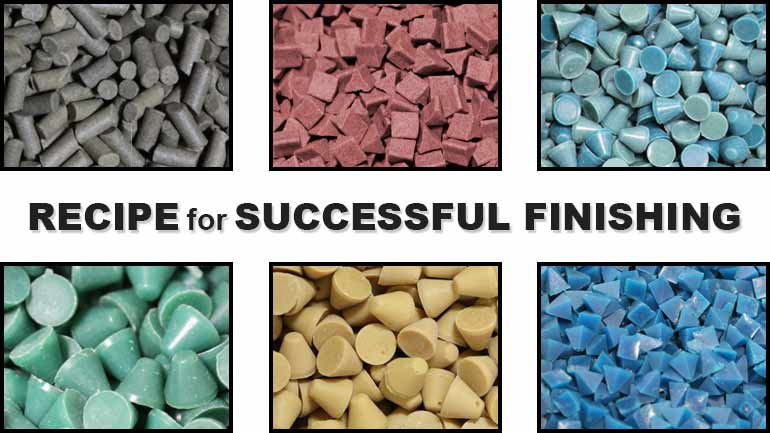

Find the Right Media Mix

Part materials and desired finishing results will dictate your specific media mix. At MFI, we provide a wide variety of finishing media materials – from synthetic materials like ceramic, plastic, porcelain, and XM to natural materials like walnut shell and corn cob – so you can find the exact specifications you need.

Our carefully curated selection of media ensures you get the right mix of media based on its composition, size, shape and performance to fully optimize your finishing process.

Keep Up with Your Replacements

It’s only natural for finishing media to wear down over time. How it’s being used, what it’s being used for, and what material it’s finishing will determine the working life of your media and the frequency of replacing your mix. Whether it’s ceramics for deburring, corn cob for dry polishing or porcelain for polishing, you’ll need to keep up with regular media mix replacement to maintain high part quality as well as to sustain maximum efficiency in your tumbling process. This is why MFI provides a wide range of replacement media mixes so you can refresh your mix when it’s time.

Let’s Build Your Recipe for Success

Here at MFI, we’re always within reach so you can experience top-tier customer service and achieve the best possible parts finishing results. Once you send us a sample part, we’ll test out various solutions in our sample processing lab to ensure a perfect match to your application. That match will then yield the same results in your facility as it did in our laboratory testing.

As the industry leader in industrial parts polishing, tumbling and deburring, we have built our business around personalization, necessary for fulfilling each customer’s requirements for finishing, including the right mix of media to achieve your target results.

To get started on finding the right media for your specific finishing requirements and cooking up your custom MFI recipe, visit our media page: https://massfin.com/media/ or contact our team at sales@massfin.com.