An alternative to vibratory finishing, centrifugal barrel finishing can surface finish 3D printed parts in significantly less time.

Additive manufacturing (AM), particularly laser powder bed fusion, enables the production of complex metal parts, but it often leaves behind a rough surface. For industries like aerospace and medical, where appearance and surface smoothness matter as much as performance, postprocessing is essential.

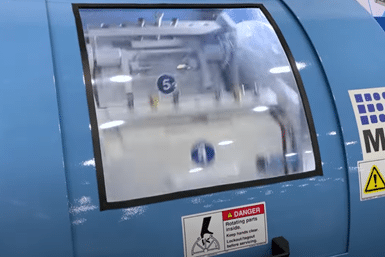

At RAPID+TCT in Detroit, we visited the booth of Mass Finishing Inc. (MFI) to learn about the company’s solution for surface finishing: centrifugal barrel finishing.

The Cool Parts Show

The Cool Parts Show focuses on a cool 3D printed part to explore how it was made and what it reveals about the possibilities of additive manufacturing. Check out the entire series here.

What Is Centrifugal Barrel Finishing?

Centrifugal finishing is a high-energy process that uses centrifugal force to rapidly polish and refine parts.

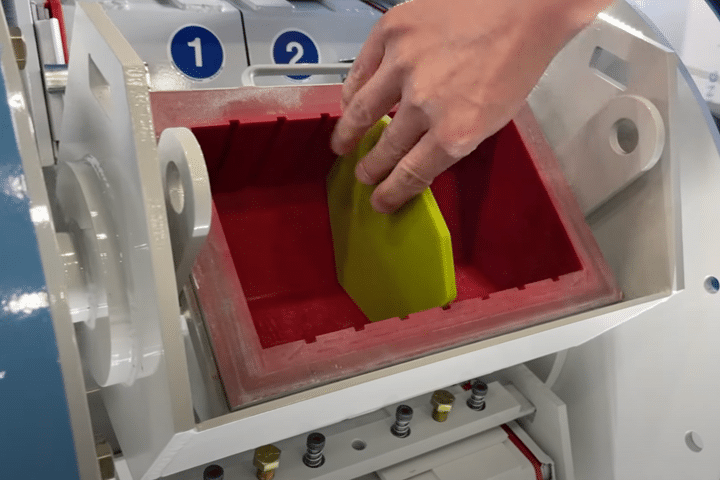

MFI’s HZ-40 system operates on the “Ferris Wheel” principle with a one-to-one ratio of barrel rotation to turret rotation. The process involves loading one or all four chambers with a mixture of parts, water, compound and media, which are filled to around 50-80% capacity. As the machine rotates, the barrels spin around the turret in a planetary motion, creating a sliding force inside the barrel.

It reaches speeds of up to 250 rpm, generating 13 Gs of force. This is in contrast to vibratory finishing, which typically generates less than 2 Gs.

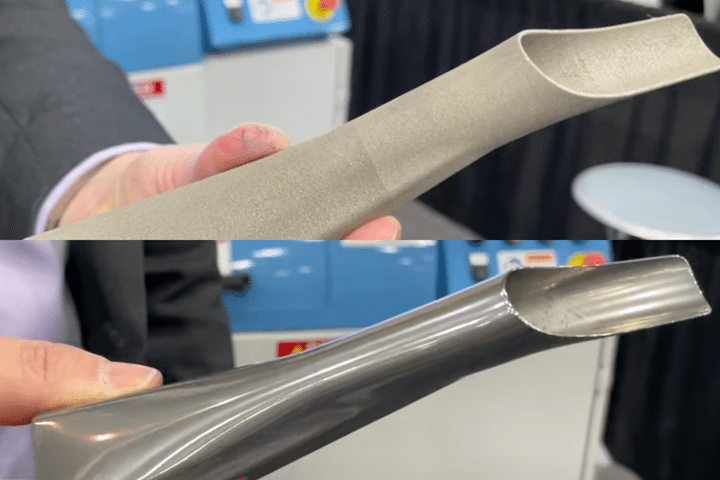

The pressure and friction created through centrifugal force removes excess material and burrs and polishes part surfaces in an operation that MFI says is quieter than vibratory tumblers. This approach achieves finishes that are isotropic, meaning parts are polished uniformly and evenly in all directions, results that are, to date, unachievable through hand finishing.

See MFI’s centrifugal barrel finishing system in our video below filmed at RAPID+TCT:

Max Part Size: 11″ L × 5.5″ D

Barrel Dimensions: 12.5″ L 6.875″ D

The increase in energy translates into time savings. Where vibratory finishing might take 10 to 20 hours to achieve a smooth surface on a metal 3D printed part, the MFI system can accomplish the same in one hour.

Versatile Media, Tailored Finishes

Different applications and materials require different abrasive media. MFI’s system accommodates a wide range. For example:

- Heavy ceramic media for hard metals like titanium, Nitinol, carbon steel and Inconel

- Plastic media for softer metals like aluminum and for plastic printed parts

Efficiency Without High Volume

An advantage of the centrifugal barrel finishing system is that it doesn’t require high part volumes to be efficient.

Each carrier can process different parts with different media at the same time. In fact, carriers can be partitioned and segmented to isolate parts during the process, preventing cross-contamination and enabling customization in one batch.

MFI’s centrifugal barrel finishing systems deliver results that reduce postprocessing time from hours to minutes. Reach out to our team today to discuss your application needs or request a sample finish.