HZ-12 Centrifugal Barrel Finisher

HZ-12 High-Energy Centrifugal

Barrel Finishing Machine

The HZ-12 is Mass Finishing’s most compact industrial high-energy finishing machine. The HZ-12 works well in small places like dental and medical device labs or in cell productions. Despite its smaller stature, it still packs the same high-end finishing punch of its bigger counterparts.

Machine Type: Compact

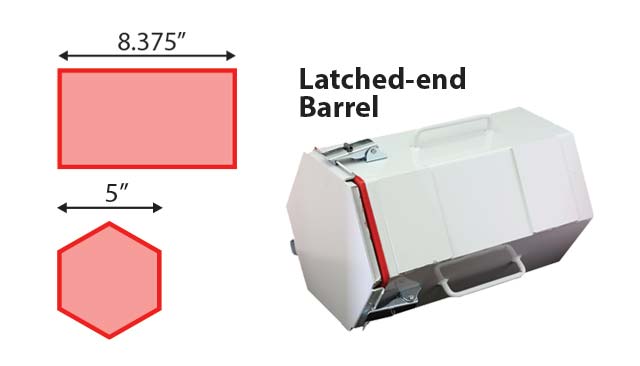

Max Part Size: 8″ L x 4.5″ D

Barrel Dimensions: 8.375″ L x 5″ D

Popular Industries: Medical, Dental, Jewelry, and Swiss Machined Parts

HZ-12 Basic Operation

The HZ-12 Centrifugal Barrel Finishing Machine is a high-energy finishing machine. It uses the pressure and friction created through centrifugal force to quickly remove excess material, polish part surfaces, and create a uniform finish. The finish achieved by the HZ-12 is isotropic, meaning parts are polished uniformly and evenly in all directions, something that cannot be achieved by hand finishing.

How It Works

Centrifugal barrel finishing, also known as centrifugal barrel tumbling, operates on the “Ferris Wheel” principle with a one-to-one ratio of barrel rotation to turret rotation. The process involves loading four barrels with a mixture of parts, water, compound, and media, which are filled to around 50-80% capacity. As the machine rotates, the barrels spin around the turret and on their own axis, creating a sliding force inside the barrel.

HZ-12 Features and Benefits

Small footprint

As our most compact machine, the HZ-12 can fit in some of the smallest locations.

Easy to maneuver

The large caster wheels on the HZ-12 base make it easy to move around the production facility.

Quieter operation

At 70 to 80 dB, our belt driven barrel tumblers are much quieter than other finishing methods such as vibratory tumbling.

Achieve a mirror-like finish

Nearly impossible to achieve by hand, our polishing machines can achieve a mirror-like finish on a variety of parts.

Short cycle times

Clean up metal, acrylic, rubber, and other materials in just minutes, rather than spending hours or days doing it by hand or using other finishing methods.

Safe and easy operation

The integral hood switch and two-button jog requirement makes these machines extremely safe to operate. The hood is securely locked during cycles.

HZ-12 Barrels

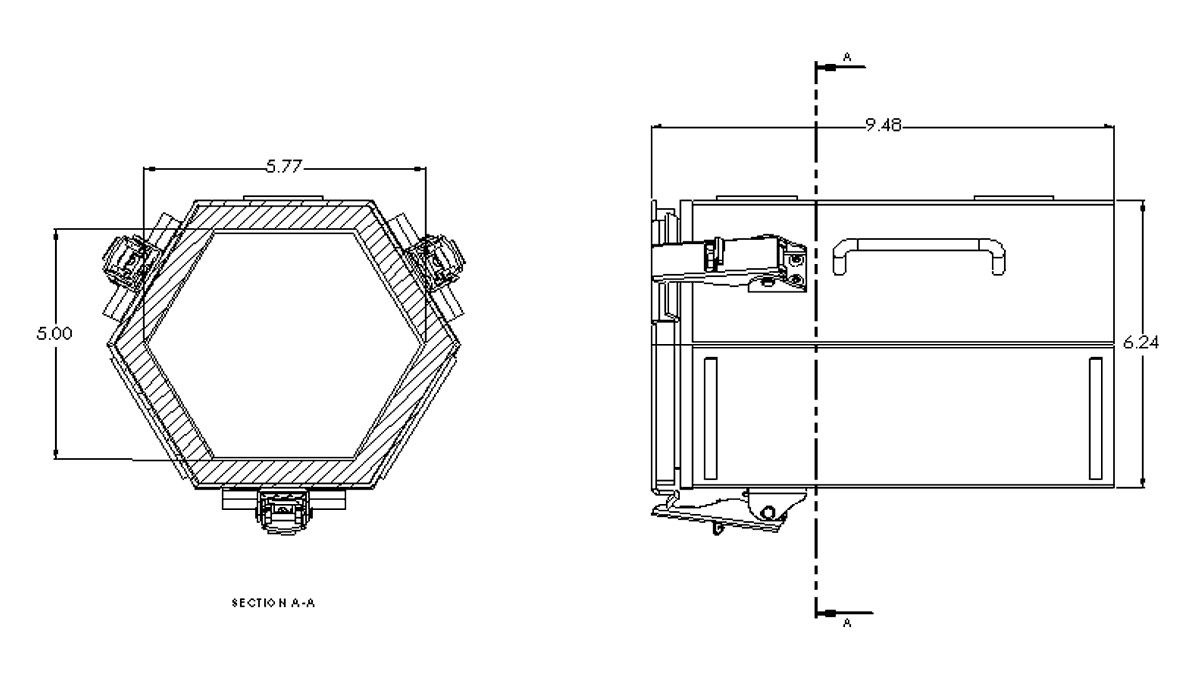

The HZ-12 Centrifugal Barrel Finisher comes standard with four removable barrels. The entire barrel is removed from the machine to load and unload media and parts. With each barrel requiring a few handfuls of media to function, these machines are great for micro-sized precision parts. This closed system doesn’t require a constant flow of water and compound, so wastewater is minimized.

By purchasing a second set of four barrels, the operator can run one set of barrels while loading and preparing another. This can dramatically reduce machine downtime.

HZ-12 Tool-Less Lockdown Bars

The HZ-12 Tool-Less Lockdown Bars are an upgrade from our original lockdown bars and are now a standard feature on all HZ-12 machines. For those still utilizing MFI’s original lockdown bars, we’re pleased to offer these upgraded bars for $265.

The Tool-Less Lockdown Bars are designed to fit seamlessly with your current machine, requiring no modifications.

The new lockdown bar design offers:

Tool-less operation

There is no longer a need for tools such as socket wrenches or drills during barrel loading, greatly simplifying the process.

Less wear and tear & reduced replacement parts

With no bolts and mechanics delivering consistent pressure, the new design eliminates the risks of over and under-tightening the barrels. This in turn reduces the wear and tear on equipment, decreasing maintenance costs and prolonging machine lifespan.

Faster and safer operation

With a more simplified installation process, less time is spent on setup, allowing you to maximize efficiency and productivity. They also reduce the risks associated with improper barrel tightening.

Get Stocked Up on the Essentials

Shop our media and compound store

HZ-12 Recommended Accessories

Processing Table

- Collect processing water and easily clean out sediment

- Reduce the mess from the finishing process

- Sludge tank can be sold separately

Media Screening Kit

- Quickly separate media from parts by dumping full barrels into various-sized screens

- Screens are sized in 1/4″ to 1/8″ increments

PLC Touchscreen

- Store processes as recipes for easy process selection

- Replaces the analog cycle start buttons

- Allows for better monitoring of machine use and time

Extra Barrels

- Dramatically reduce downtime on the machine

- Load and unload the second set of barrels while the machine is running

Additional HZ-12 Specs & Resources

Specifications

Main Motor |

|

Voltage |

|

Total Capacity |

|

Approximate Shipping Weight |

|

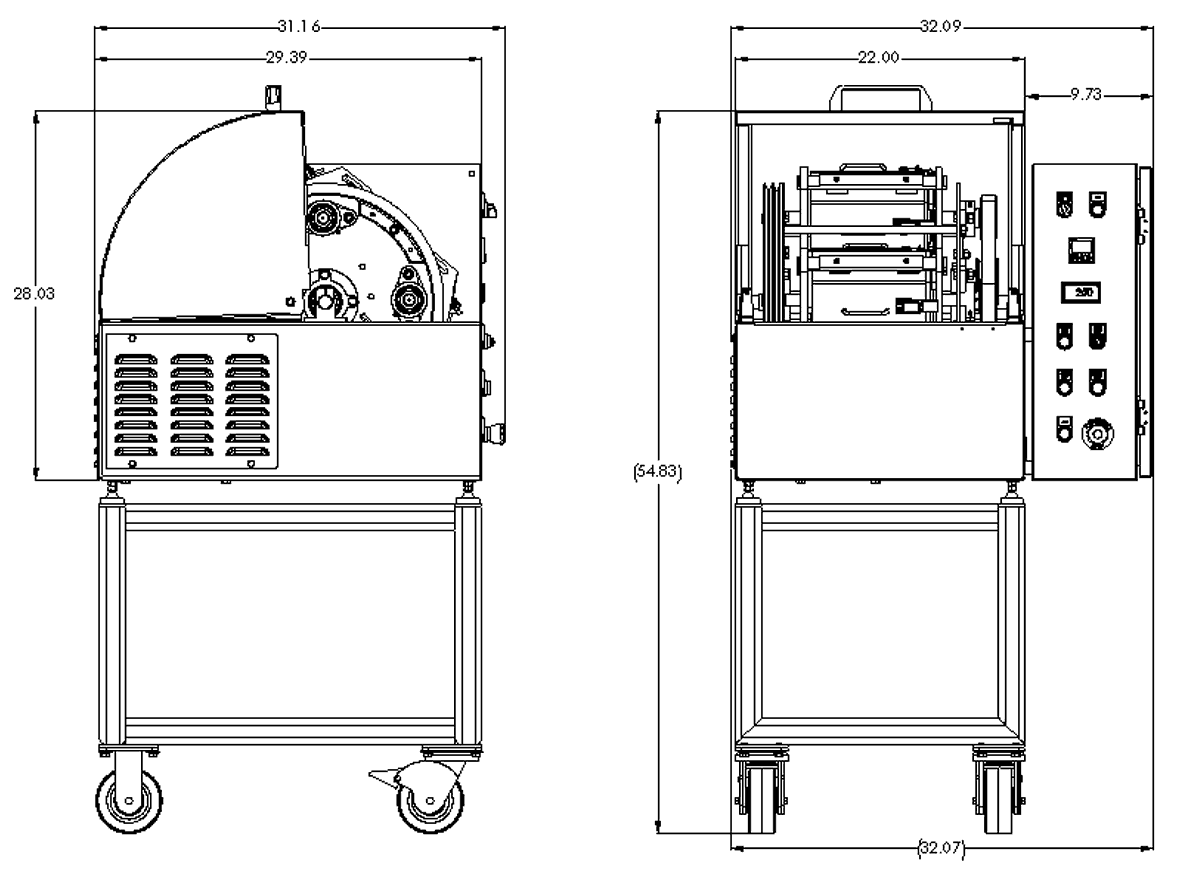

Overall Dimensions |

|

Machine Construction |

|

Paint |

|

Barrel Construction |

|

Control Panel |

|

Brake |

|

Safety Interlock |

|

Are You Interested in the HZ-12?