HZ-40 Centrifugal Barrel Finisher

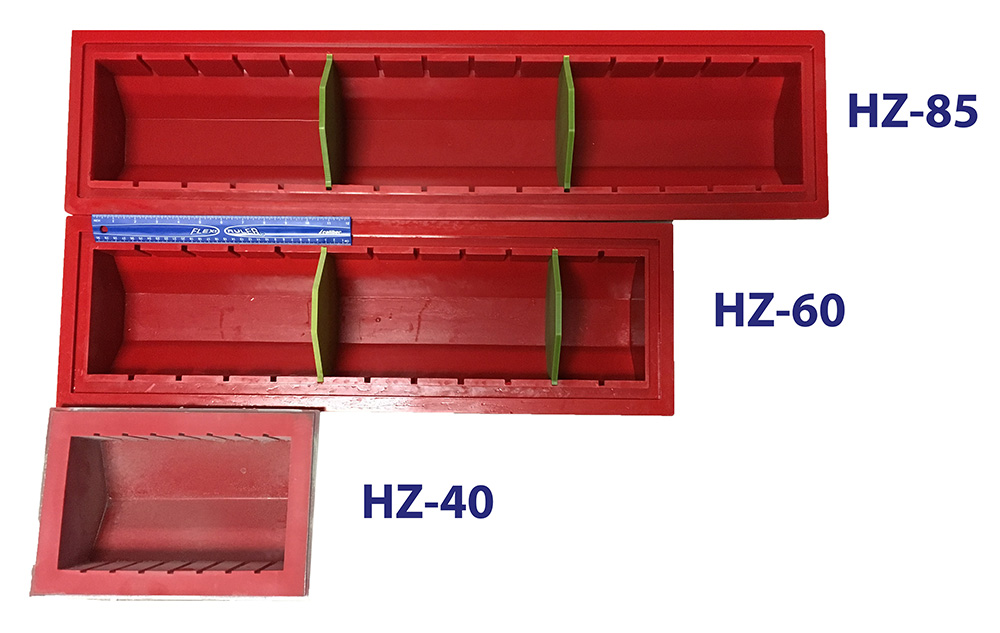

HZ-40 Centrifugal Barrel

Finishing Machine

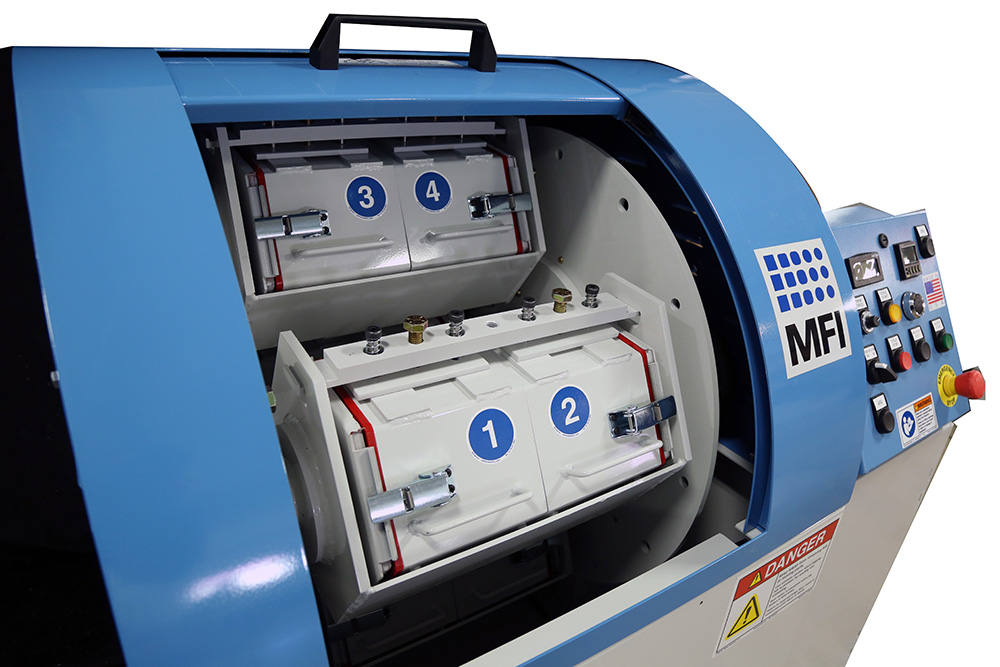

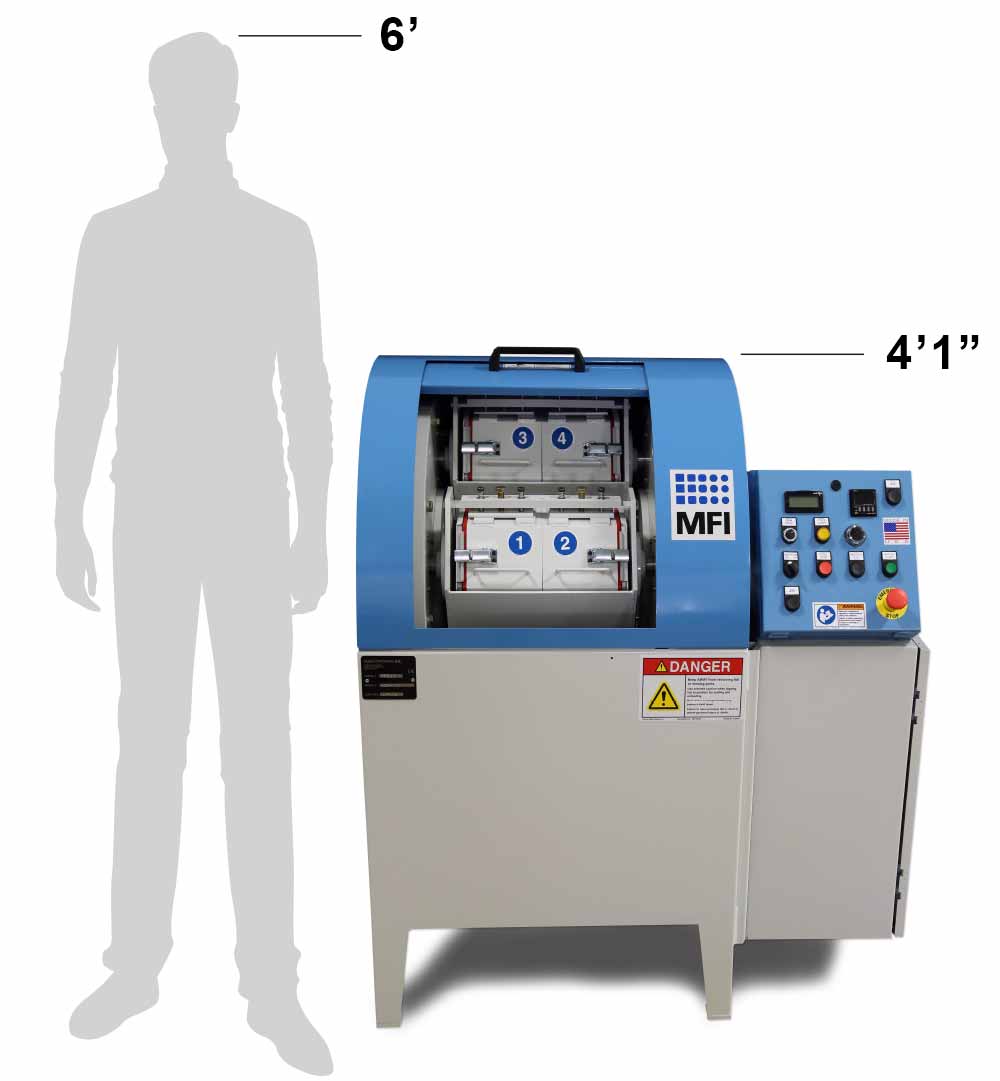

The HZ-40 is one of MFI’s most popular industrial finishing machines and is ideal for precision part manufacturers. The small footprint (4′ x 3′) makes it easy to fit into most productions without sacrificing any finishing speed or results. Moreover, its compact size and multiple barrel styles provide flexibility for work in nearly any industry. Despite its smaller stature compared to other stock barrel tumblers, HZ-40 centrifugal machine still packs the same high-end finishing punch as its bigger counterparts.

Machine Type: Compact

Max Part Size: 11″ L x 5.5″ D

Barrel Dimensions: 12.5″ L x 6.875″ D

Popular Industries: Additive Manufacturing, Medical & Surgical, Precision Part Manufacturers

HZ-40 Basic Operation

The HZ-40 Centrifugal Machine is a high-energy finishing machine. It uses the pressure and friction created through centrifugal force to quickly remove excess material and burrs, polish part surfaces, and create a uniform finish. Then, the finish achieved by the HZ-40 is isotropic, meaning parts are polished uniformly and evenly in all directions, something that cannot be achieved by hand finishing.

How It Works

Centrifugal barrel finishing, also known as centrifugal barrel tumbling, operates on the “Ferris Wheel” principle with a one-to-one ratio of barrel rotation to turret rotation. The process involves loading one or all four chambers with a mixture of parts, water, compound, and media, which are filled to around 50-80% capacity. As the machine rotates, the barrels spin around the turret in a planetary motion, creating a sliding force inside the barrel.

HZ-40 Features and Benefits

Small footprint

Our second-smallest machine. This compact machine can easily fit in some of the smallest locations.

Barrel versatility

With removable barrels and 4 different barrel options (two-sided, bolted-end, latched-end, and half-latched), this machine is extremely versatile.

Quieter operation

Much quieter than other finishing methods such as vibratory tumblers.

Achieve a mirror-like finish

Nearly impossible to achieve by hand, our polishing machines can achieve a mirror-like finish on a variety of parts.

Short cycle times

In a matter of minutes clean up metal, acrylic, rubber, and other materials in what could take hours or even days by hand finishing.

Safe and easy operation

The integral hood switch and two-button jog requirement makes this finishing machine extremely safe to operate. The hood is securely locked during cycles.

HZ-40 Barrels

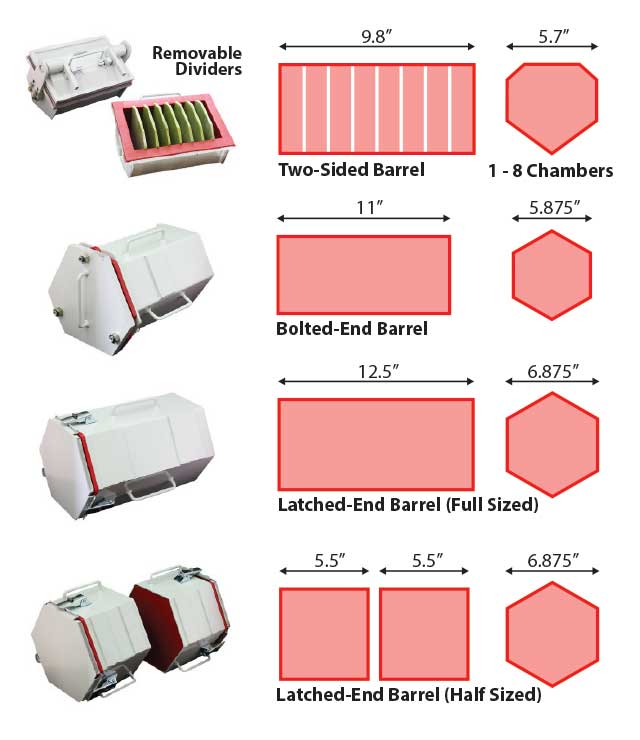

The HZ-40 Centrifugal Machines can be outfitted with four styles of removable barrels. These options include the two-sided, bolted-end, latched-end, and half-latched barrels.

By purchasing a second set of barrels, the operator can run one set while loading and preparing another. Consequently, this can dramatically improve production efficiency.

Two-Sided Barrel (Aluminum or Steel)

- Allows the use of removable barrel dividers to keep parts separated, avoiding part-to-part impingement and damage

- Heavy-duty cam locks with safety lock pins

Bolted-End Barrel

- Best for high pressure

- Heavy-duty hardware for rough environments

Latched-End Barrel (Full-Size)

- Largest Capacity

- Snapping latches for quick lid removal

Latched-End Barrel (Half-Size)

- Light and easy to get in and out of the machine

- Latches for quick lid removal

- 2 barrels per cradle (8 total)

Get Stocked Up on the Essentials

Shop our media and compound store.

HZ-40 Recommended Accessories

Processing Table

- Collect processing water and easily clean out sediment

- Reduce the mess from the finishing process

- Sludge tank can be sold separately

Vibratory Media Separator

- Dump full barrels onto vibrating screen deck to quickly separate parts from tumbling media

- Removable wire mesh screens for different part sizes

- Custom screens also available

PLC Touchscreen

- Store processes as recipes for easier operation

- Replaces the analog cycle start buttons

- Allows for better monitoring of machine use and time

- Maintenance reminders programmed in based on hour meter

Extra Barrels

- Dramatically reduce downtime on the machine

- Load and unload the second set of barrels while the machine is running

Additional HZ-40 Specs & Resources

| Main Motor Hp |

|

| Voltage |

|

| Total Capacity |

|

| Variable Speed Drive |

|

| Approximate Shipping Weight |

|

| Overall Dimensions |

|

| Machine Construction |

|

| Barrel Construction |

|

| Control Panel |

|

| Brake |

|

| Barrel Options | |

| Two-Sided Barrels |

|

| Bolted-End Barrels |

|

| Latched-End Barrels (Full Sized) |

|

| Latched-End Barrels (Half Sized) |

|

- An MFI customer HZ-40 set up with Processing Table and Tank along with a Media Storage Rack.

- An MFI customer HZ-40 set up with Processing Table and Tank along with a Media Storage Rack.

- An MFI customer HZ-40 set up with Processing Table and Tank along with a Media Storage Rack.

- An HZ-40 next to an HZ-120 in a production setting.

- An HZ-40 installed in a 3D printing cell.

| Barrel Type | Empty | Ceramic Media | Plastic Media |

| Two-Sided, Aluminum | 17 | 23 | 20 |

| Two-Sided, Steel | 24 | 30 | 26 |

| Half-Size, Latched End | 12 | 23 | 20 |

| Full-Size, Latched End | 24 | 49 | 43 |

| Bolted End Barrel | 24 | 40 | 36 |

| HZ-12 Latched End Barrel | 12.5 | 21 | 19 |

| Free Standing Media Separator |

|

| Work Station and Sludge Tank |

|

| Electric Hoist |

|

| Media Screen Kit |

|

| Media Drain Basket |

|

| PLC Controller |

|

| Barrel Dividers |

|

| Light Tower Indicator |

|

| Infrared Safety Light Curtains |

|

| Media and Compound |

|

|

Centrifuge Module CF55 SD Series Microseparator™

|

|

| Media Storage Rack |

|

Are You Interested in the HZ-40?