W-5 Vibratory Finishing Tub

W-5 Vibratory Tub Finishing Machine

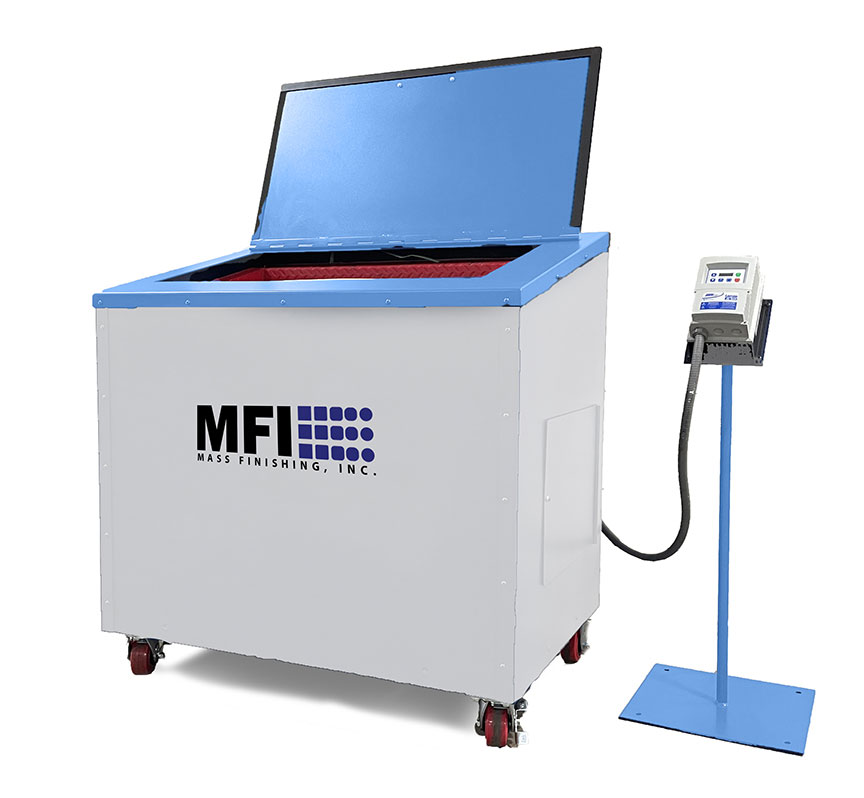

The MFI W-5 Vibratory Finishing Tub is a versatile and cost-effective piece of equipment that can be used for a variety of metal and plastic finishing applications. The industrial caster wheels make it easy to move the unit around the shop floor, allowing manufacturers to perform vibratory tumbling, polishing, or deburring in-house and on demand.

About the W-5 Vibratory Tub

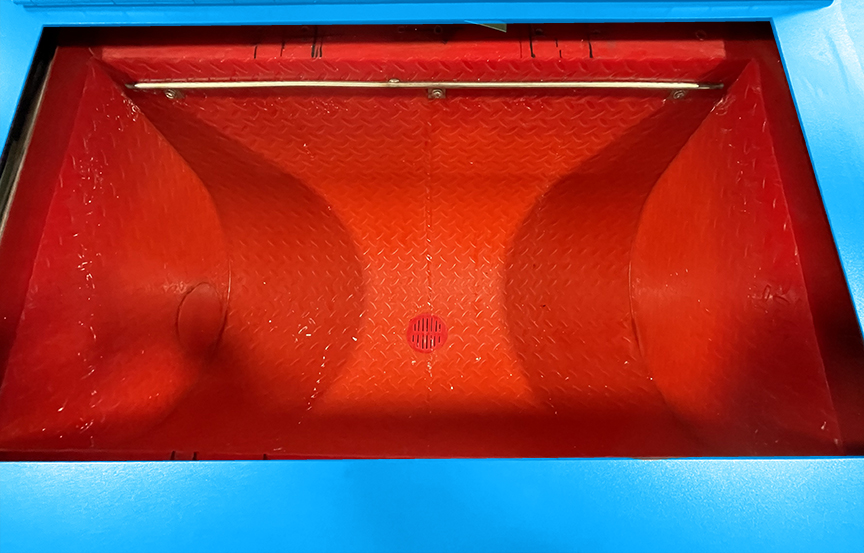

The W-5 Vibratory Finishing Tub is designed to be easy to maintain. The polyurethane-lined tub is durable and long-lasting, and the machine is equipped with a sound cover to reduce noise levels and keep the process contained. The W-5 is its ability to run both wet and dry media, depending on the application. This makes it a versatile choice for manufacturers who need to finish a variety of parts.

W-5 Features

The W-5 Vibratory Tub finishing machine comes with a range of standard features, including:

- An electronic variable speed drive

- Digital tachometer

- Balanced suspension vibration unit

- Hinged sound cover

- Media discharge door

- 10 gallon settling tank and recirculation pump

W-5 Video Demo

W-5 Basic Operation

The MFI W-5 Tub operates using an electric motor to drive an unbalanced shaft, which creates a powerful vibratory action in the polyurethane-lined tub. Inside the tub, abrasive or non-abrasive media rolls in a large mass, providing a gentle yet thorough finish on your parts. Simply drop your unfinished parts into the mass and let the W-5 Tub do the rest. After a specified amount of time, your parts will be removed and left smoothed and free of sharp edges and burrs.

Additional W-5 Specs & Resources

Specifications

Main Motor HP |

|

*230/460, 3 Phase, 60 cycle motor Option |

|

Voltage |

|

Total Capacity |

|

Internal Tub Dimensions |

|

Approximate Shipping Weight |

|

Overall Dimensions |

|

Total Footprint |

|

Media Discharge Height |

|

Machine Construction |

|

Tub Construction |

|

Vibratory Mechanism |

|

Unloading System |

|

Compound Pump |

|

Options

Cartridge auto grease system |

|

100 gallon settling tank |

|

Compound Auto Flow |

|

Media and Compound |

|

Tub Divider |

|

Are You Interested in the W-5 Vibratory Tub?