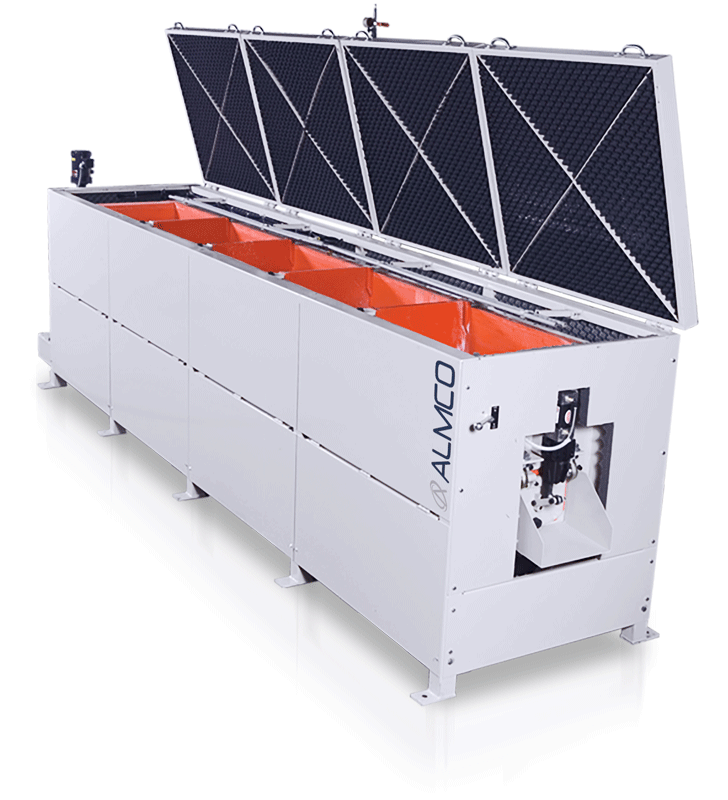

V Series Vibratory Tubs

V Series Vibratory Finishing Tubs

The V Series Vibratory Tubs are manufactured by our sister company, ALMCO, and are an upgraded version of our VB Line. The V Series has a much larger part and volume capacity and features variable speed and automated discharge. These machines are highly customizable and are designed for continuous daily use, providing a cost-effective finishing solution for a variety of part sizes and quantities.

About the V Series Vibratory Tubs

The V Series Vibratory Tubs have many more automated features and optional add-ons in comparison to the VB Series vibratory tubs. Material handling systems can be added for full automation, and they can also be customized with rotating part fixtures to prevent part-on-part contact.

Features:

- Wet or dry processing capabilities

- Variable amplitude for process adjustment

- Heavy-duty polyurethane lining

- Ability to run steel media

- Automated loading and unloading

- Low-high volume production

Optional Items:

- Automatic lubrication system

- Automated loading and unloading

- Flowmeter

- Tub divider

- Air-operated discharge door

- Free-standing sound enclosure

- PLC and touchscreen controls

- UA 508A electrical controls

V Series Vibratory Tub

Basic Operation

When parts and media are put into the tub of the vibratory machine, the counterweights on the spinning vibrator shaft make the processing tub shake on its springs. This shaking makes the parts and media inside the tub vibrate and roll in an organized way. This action causes parts and media to contact each other, achieving a wide variety of finishing applications from deburring, descaling, polishing, cleaning, and even flash removal. You can control the rolling action by adjusting the speed of the vibrator assembly and the amount of counterweight.

Available V Series Models

| Model No. | Working Capacity (cu ft) | Tub Cross Section (in) | Tub Length (in) | Drive HP | Overall Dimensions (in) |

|---|---|---|---|---|---|

| V-1934 | 6.5 | 19″ | 34″ | 7.5 | 76 x 44 x 48 |

| V-1661 | 8.25 | 16″ | 61″ | 10 | 110 x 39 x 44 |

| V-2334 | 10 | 23″ | 34″ | 10 | 81 x 85 x 61 |

| V-1696 | 13 | 16″ | 96″ | 15 | 146 x 40 x 50 |

| V-2345 | 13 | 23″ | 45″ | 15 | 100 x 48 x 69 |

| V-16155 | 20 | 16″ | 155″ | 20 | 204 x 40 x 52 |

| V-19114 | 22 | 19″ | 114″ | 15 | 164 x 41 x 54 |

| V-16186 | 25 | 16″ | 186″ | 20 | 230 x 40 x 53 |

| V-19155 | 30 | 19″ | 155″ | 25 | 205 x 41 x 54 |

| V-23142 | 38 | 23″ | 142″ | 40 | 210 x 50 x 65 |

| V-23189 | 48 | 23″ | 189″ | 50 | 255 x 48 x 65 |

| V-2842 | 14.5 | 28″ | 42″ | 15 | 94 x 55 x 64 |

| V-2872 | 25 | 28″ | 72″ | 25 | 140 x 55 x 70 |

| V-3347 | 21 | 33″ | 47″ | 25 | 94 x 58 x 75 |

| V-3372 | 34 | 33″ | 72″ | 30 | 141 x 58 x 75 |

| V-3396 | 46 | 33″ | 96″ | 40 | 163 x 62 x 75 |

| V-4448 | 38 | 44″ | 48″ | 40 | 120 x 78 x 93 |

| V-4460 | 49 | 44″ | 60″ | 40 | 145 x 125 x 88 |

| V-6548 | 89 | 65″ | 48″ | 60 | 134 x 110 x 144 |

Are You Interested in the V Series Vibratory Tub?