Additive manufacturing and 3D printing have revolutionized the manufacturing industry, allowing for the production of highly complex and customized parts. However, achieving the desired surface finish on these printed parts can be a challenge. At Mass Finishing Inc. (MFI), we have been providing parts finishing solutions for over two decades. We’re a trusted partner in the Additive Manufacturing and 3D printing industries, offering high-quality solutions to help companies achieve the finish they are looking for.

MFI’s commitment to the Additive Manufacturing and 3D printing industry extends beyond providing exceptional solutions. We actively participate in industry events and trade shows to stay updated on the latest trends and connect with professionals and experts. We recently exhibited at the RAPID + TCT tradeshow in Chicago, IL this May. Engaging with industry professionals allowed us to showcase our expertise, receive valuable feedback, and further enhance our solutions.

The Challenge of Surface Finishing in Additive Manufacturing

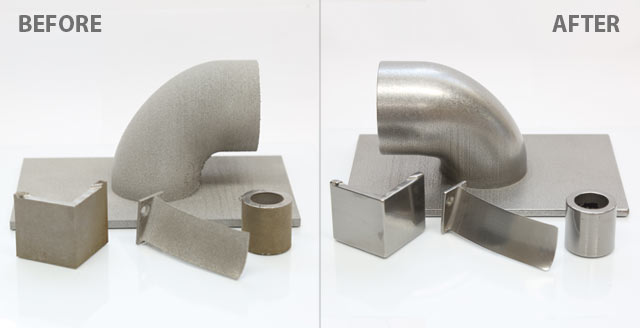

The additive manufacturing and 3D printing process often leaves behind rough surfaces and imperfections on the printed parts. These surfaces need to be smoothed and polished to meet the quality standards of various industries, such as aerospace, automotive, medical, and more. Traditional hand polishing methods can be time-consuming and labor-intensive, leading to increased production time and costs. This is where MFI’s expertise in mass finishing comes into play.

MFI’s High-Energy Centrifugal Barrel Finishing Machines, specifically our HZ-Series, offer a quick and effective post-processing solution for improving surface roughness and achieving a high polish on 3D printed or additive manufactured parts. The combination of sufficient force generated by the machines and the use of highly abrasive tumbling media enables the removal of surface roughness and scale, resulting in a smooth and polished surface. The result is a high-quality finish that meets the stringent requirements of various applications, including aerospace components, medical implants, engine parts, and more.

With our HZ-Series machines, companies can significantly reduce the time required for surface finishing. Unlike traditional hand polishing methods that can take days to achieve the desired finish on complex parts, our machines can polish multiple parts simultaneously, reducing the process time to just two hours. This efficiency translates into reduced labor costs and improved production throughput, allowing companies to meet tight deadlines and increase their overall productivity.

Average Process Times

| Light Edge Break/Deburr | 20 – 30 minutes |

| Rough Grind/Deburr | 60 – 120 minutes |

| Full Polish from Raw Part | 90 – 150 minutes |

*Achieving a polish on a 3D Printed part depends greatly on the material and the initial roughness and scale left over from the printing process.