Metal parts tumblers are key in industrial finishing, deburring, and polishing. This article provides an overview of their functionality and impact on efficiency and quality, featuring Mass Finishing Inc.’s (MFI) advanced high-energy technology for tumbling metal parts.

What is a metal parts tumbler?

A metal parts tumbler is an essential tool in the manufacturing world, designed for finishing, deburring, and polishing various metal parts. At MFI, we specialize in industrial metal parts tumblers, which are designed to stand up to the wear-and-tear of those in the industrial equipment and metal fabrication industries, as well as contract manufacturers and job shops.

MFI’s HZ-Series High-Energy Centrifugal Barrel Finishing Equipment caters to both small precision parts and large-scale industrial components, ensuring consistency and precision in your manufacturing processes.

Types of metals finished

MFI’s metal parts tumblers handle a variety of materials, including:

- Heat-Treated Steel

- Aluminum

- Stainless Steel

- Tool Steel

- Hardened Steel

- Carbon Steel

- Brass

The technology behind tumbling metal parts

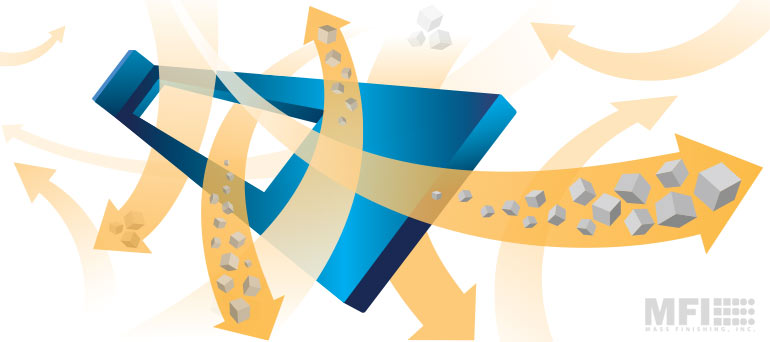

MFI’s centrifugal barrel tumbling systems utilize a high-energy tumbling process, perfectly suited for metal parts finishing, deburring, and polishing.

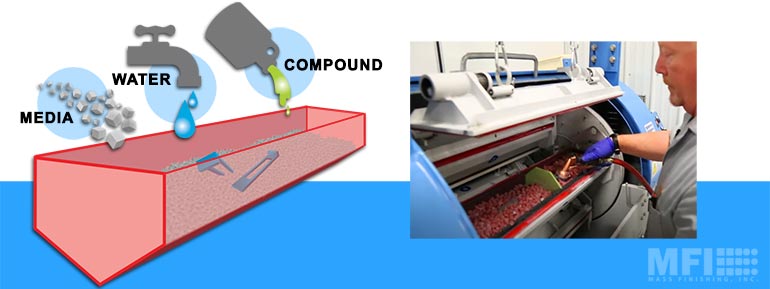

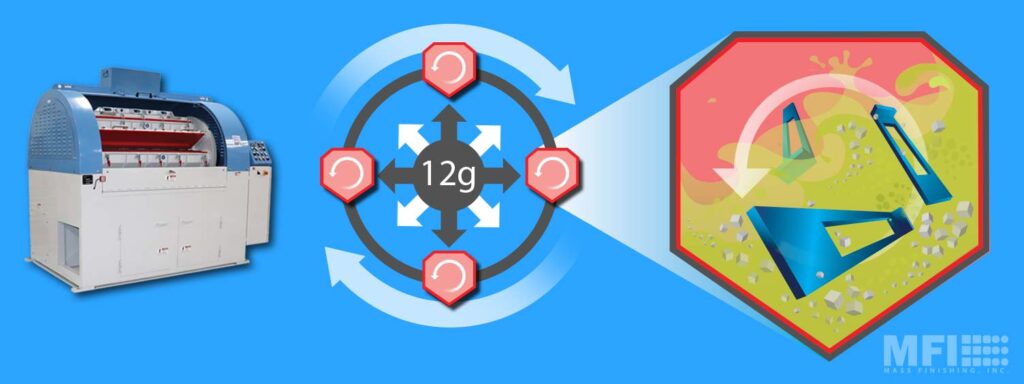

Metal parts are placed in four hexagon-shaped barrels filled with media, water, and compound. Utilizing a planetary motion, these barrels then spin around a central turret, creating powerful centrifugal forces, sometimes up to 12 times that of gravity (12G).

This rapid spinning creates intense friction and pressure inside the barrels, causing the metal parts and finishing materials to rub against each other. This intense rubbing action helps effectively eliminate tough burrs and sharp edges from metal parts, providing smoother and more consistent finishes.

With the use of multiple barrels and barrel dividers, operators are able to easily separate parts into their own compartment. The option to create separate compartments within the four machine barrels helps to avoid part-on-part impingement and damage.

Industrial advantages of metal parts tumblers

Eliminate hand finishing

One of the standout benefits of our metal parts tumblers is their ability to significantly reduce the need for handwork and manual labor. Traditional hand finishing is not only time-consuming and costly but also inconsistent and risky. MFI’s industrial metal parts tumblers offer a repeatable, efficient process, ensuring uniformity in finishing and reducing the physical demands placed on workers.

Comprehensive Finishing Capabilities

From deburring to achieving mirror-like polishes, our tumblers are equipped to handle diverse finishing needs. Operators can choose the finish they want depending on the media used, process time, and the barrel speed. This adaptability ensures that regardless of the metal or part complexity, the outcome is consistent and repeatable.

Efficiency, Quality, and Cost-Effectiveness

The high-energy finishing of the HZ-Series machines provides a consistent, isotropic finish, improving part lifespan and quality. This mechanized process is more economical, slashing labor costs and dramatically cutting down production time.

Centrifugal barrel finishers have much shorter cycle times in comparison to vibratory equipment and traditional methods, making it possible to deburr and polish parts in minutes.

How to choose the right metal parts tumbler

Selecting the right tumbler for metal parts involves considering the:

- Part size

- Part type

- Volume of parts

At MFI, we understand that every part is unique. We offer a range of tumbling machines for metal parts, stocking nine different sizes to suit different parts and production volumes, depending on your requirements and application.

From our compact HZ-12 for smaller parts, to the high-capacity HZ-330 for larger scale operations, we offer a variety of sizes and price points suitable for any application.

HZ-12

Mass Finishing’s most compact industrial high-energy finishing machine. The HZ-12 works well in small places like a lab, or in production cells.

Machine Type: Compact

Max Part Size: 8″ L x 4.5″ D

Barrel Dims: 8.375″ L x 5″ D

HZ-40

MFI’s most popular model, ideal for precision part manufacturers. The small footprint (4′ x 3′) makes it easy to fit into most productions without sacrificing any finishing speed or results. Its compact size and multiple barrel styles provide flexibility for work in nearly any industry.

Machine Type: Compact

Max Part Size: 11″ L x 5.5″ D

Max Barrel Dims: 12.5″ L x 6.875″ D

HZ-60

Known for its high efficiency, the HZ-60 provides more than double the capacity and efficiency when compared to MFI’s compact centrifugal barrel tumblers.

Machine Type: High Efficiency

Max Part Size: 25.25″ L x 5.25″ D

Barrel Dims: 25.75″ L x 5.8″ D

HZ-85

Shares similarities with MFI’s HZ-60 but offers a larger capacity. With almost 8” larger barrels than the HZ-60, it is an ideal machine for those that require more space to process their parts.

Machine Type: High Efficiency

Max Part Size: 33″ L x 5.25″ D

Barrel Dims: 33.5″ L x 5.8″ D

HZ-120

Known for its wide diameter and deep barrels. With over triple the capacity of MFI’s compact machines like the HZ-40, you can finish larger and higher quantities of parts per cycle.

Machine Type: Wide Diameter

Max Part Size: 16″ L x 9.5″ D

Barrel Dims: 17″ L x 10.25″ D

HZ-160

Shares similarities with MFI’s HZ-120, but with longer and deeper barrels. With over double the capacity of MFI’s wide diameter machines like the HZ-60 and HZ-85, you can finish larger diameter or higher quantity parts for even greater efficiency.

Machine Type: Wide Diameter

Max Part Size: 20″ L x 11″ D

Barrel Dims: 20.625″ L x 11.8″ D

HZ-175

Known for having the longest barrels of all the HZ-Series machines at 48” long. It also has a wider diameter than half the models that MFI offers. This longer barrel capacity caters perfectly to customers with medium-sized parts that are longer than average.

Machine Type: High Efficiency

Max Part Size: 47″ L x 7″ D

Barrel Dims: 48″ L x 8″ D

HZ-220

With a total capacity of 8 cubic feet, it is the second-largest machine in our HZ-Series, making it an ideal choice for those with large parts or high production volumes.

Machine Type: High Capacity

Max Part Size: 26.5″ L x 10″ D

Barrel Dims: 27.375″ L x 11″ D

HZ-330

MFI’s largest capacity full-size industrial finishing machine, offering ample space for processing parts. With long and deep barrels, this machine is ideal for those needing to process higher volume parts or for those needing a machine that can handle large parts.

Machine Type: High Capacity

Max Part Size: 40.75″ L x 11″ D

Barrel Dims: 41.4″ L x 11.9″ D

Our Max Part Size Chart can assist you in identifying the most suitable machine for your needs.

Why choose MFI as your metal parts tumbler supplier

Unmatched Support and Customization

Beyond our diverse product range, MFI stands out for its comprehensive customer support. We provide in-house and virtual assistance, ensuring that you have expert guidance at every step.

Parts Processing Assistance

MFI provides no cost and no obligation parts processing assistance to help determine the best finishing processes for your needs. All it takes is two simple steps!

- Fill out our Test Sample Request Form

- Send your sample parts to our lab

From there, we’ll review your parts along with the information you provided. Our team will then determine the right equipment, media size and composition based on your specifications and desired finish. This is all at no cost to you!

Maintenance and Educational Resources

Access to our maintenance schedules and extensive library of process videos guarantees that your equipment remains in top condition, prolonging its service life and efficiency.

Conclusion

MFI’s metal parts tumblers are ideal for a variety of part sizes, shapes, and production levels. By automating and standardizing finishing processes, they eliminate the inconsistencies and physical strain of manual labor.

Contact us at sales@massfin.com or call 320-543-3222. Let’s discuss how our metal parts tumblers can enhance your production efficiency and quality.