Centrifugal Barrel Finishers

HZ-Series High Energy Centrifugal Barrel Finishing Machines

The HZ-Series Centrifugal Barrel Finishing Machines are our main expertise. These high-energy finishing machines feature four chambers that rotate around like a ferris wheel to create centrifugal force to finish and polish parts. They are the fastest and most economical form of tumble finishing equipment available. A wide range of industries utlilize these tumblers to polish, deburr, and deflash a variety of metal and non-metal components. From aerospace jet engine blades to medical implants, our HZ-Series machines are a versatile and reliable solution for achieving a cost-effective finishing result. What sets MFI apart when compared to other tumbling manufacturers is our support and experience with utilizing this type of equipment.

Benefits

- Reduce handwork and manual labor

- Easy to keep parts separated

- Quieter operation

- Achieve an isotropic mirror-like finish that is impossible to achieve by hand

- Short cycle times for faster turnaround and higher productivity

Available HZ-Series Models

We understand that every part is unique. MFI offers nine stock sizes of centrifugal barrel tumbling machines to suit different parts and production volumes, depending on your requirements and application.

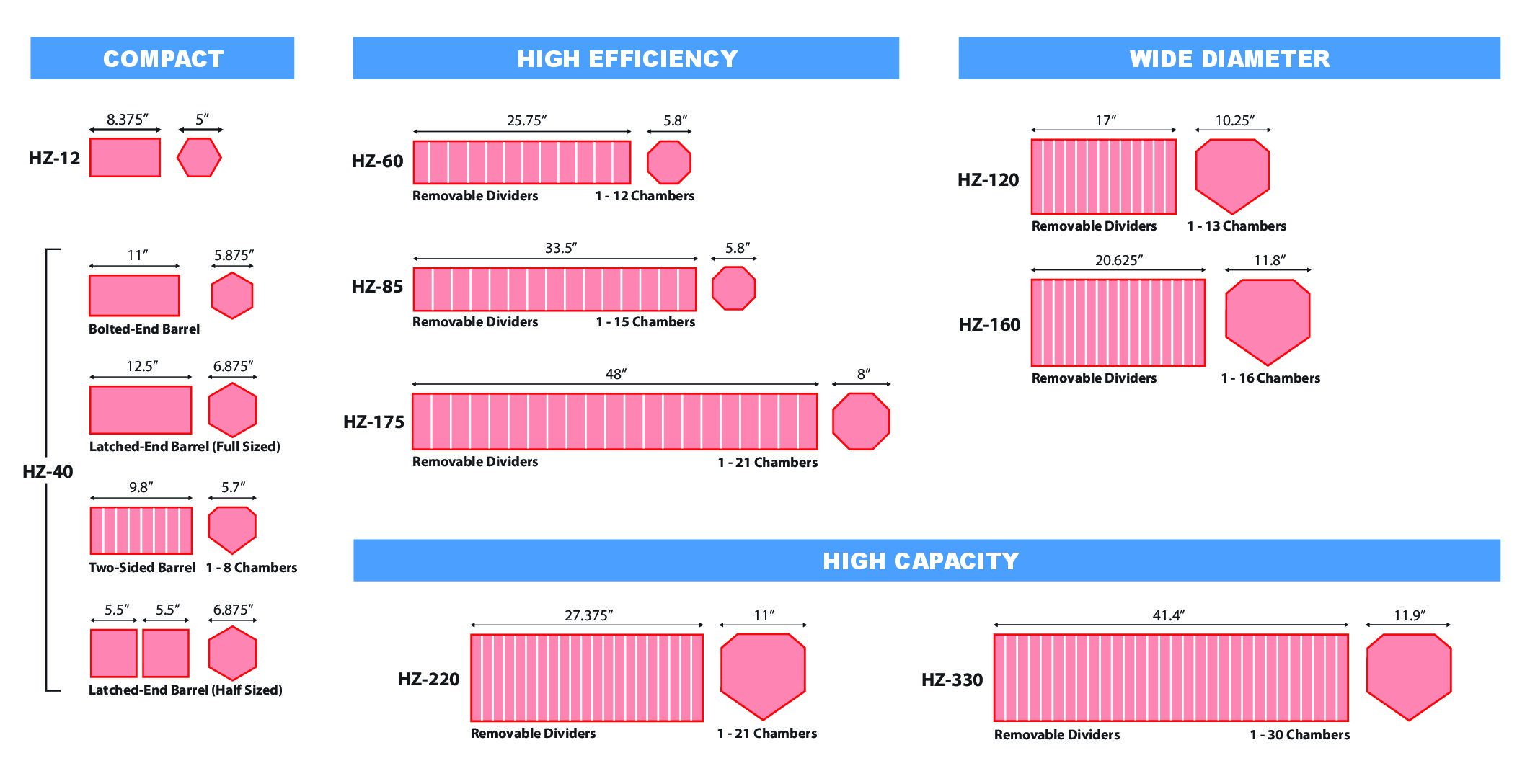

HZ-12

Machine Type: Compact

Max Part Size: 8″ L x 4.5″ D

Barrel Dims: 8.375″ L x 5″ D

Popular Industries: Dental and Jewelry

HZ-40

Machine Type: Compact

Max Part Size: 11″ L x 5.5″ D

Max Barrel Dims: 12.5″ L x 6.875″ D

Popular Industries: Additive Manufacturing, Medical & Surgical, Precision Part Manufacturers

HZ-60

Machine Type: High Efficiency

Max Part Size: 25.25″ L x 5.25″ D

Barrel Dims: 25.75″ L x 5.8″ D

Popular Industries: Automotive & Transportation, Medical

HZ-85

Machine Type: High Efficiency

Max Part Size: 33″ L x 5.25″ D

Barrel Dims: 33.5″ L x 5.8″ D

Popular Industries: Aerospace, Firearm & Munitions, Knives

HZ-120

Machine Type: Wide Diameter

Max Part Size: 16″ L x 9.5″ D

Barrel Dims: 17″ L x 10.25″ D

Popular Industries: Contract Manufacturing & Job Shops

HZ-160

Machine Type: Wide Diameter

Max Part Size: 20″ L x 11″ D

Barrel Dims: 20.625″ L x 11.8″ D

Popular Industries: Automotive & Transportation, Contract Manufacturing & Job Shops, Rubber

HZ-175

Machine Type: High Efficiency

Max Part Size: 47″ L x 7″ D

Barrel Dims: 48″ L x 8″ D

Popular Industries: Firearms & Munitions, Knives

HZ-220

Machine Type: High Capacity

Max Part Size: 26.5″ L x 10″ D

Barrel Dims: 27.375″ L x 11″ D

Popular Industries: Automotive & Transportation, Fabricated Metal Products, Rubber

HZ-330

Machine Type: High Capacity

Max Part Size: 40.75″ L x 11″ D

Barrel Dims: 41.4″ L x 11.9″ D

Popular Industries: Automotive & Transportation

The Benefits of Centrifugal Barrel Finishing

Reduce handwork & manual labor

Deburring and polishing parts one at a time by hand is time-consuming, expensive, demanding, and dangerous. Our HZ-Series Finishing Machines take the handwork out of finishing. It also provides users with greater consistency in their finishing of parts.

Easy to keep parts separated

A key advantage with barrel tumbling is the ability to easily separate work pieces into their own compartment using barrel dividers. This helps to avoid part-on-part impingement and damage caused by parts hitting each other.

No tooling required

Unlike drag finishing or robotic solutions, barrel tumbling doesn’t require expensive tooling. As long as the part fits in the barrel, it’s a candidate for barrel finishing.

Quieter operation

Compared to vibratory equipment, this series runs much quieter. They can be installed in places you wouldn’t want vibratory machines installed, such as where other machines’ tolerances may be affected.

Achieve a mirror-like finish

Nearly impossible to achieve by hand, our barrel polishing machines achieve an isotropic mirror-like finish on a variety of parts. This means the finish is omnidirectional with no sanding or polishing lines.

Short cycle times

In a matter of minutes, centrifugal barrel finishers can clean up metal, acrylic, rubber, and other materials in what could take hours or even days by hand. Some customers have reduced cycle times from 20 hours to just 30 minutes.

Range of finishing capabilities

With the ability to control the speed of the tumble with variable frequency control, the operator can achieve a simple polish at low speed or even full-scale deburring and radiusing at higher speeds.

What is High-energy Centrifugal Barrel Finishing?

Centrifugal barrel finishing is a type of high-energy tumble finishing that uses centrifugal force to subject parts and media to pressures greater than the force of gravity. Our HZ-Series machines reach upwards of 12 times the force of gravity (12G). Centrifugal Barrel Finishing Machines (CBF) use this pressure and friction to quickly remove excess material, polish part surfaces, and create a uniform finish. Often called “tumblers” or “harperizers,” they are utilized to achieve a variety of finishes, including polishing, deburring, and deflashing parts. Centrifugal barrel tumblers can achieve a smoother surface finish in a fraction of the time of other finishing methods such as vibratory finishing, resulting in shorter processing times and consistent results.

How does Centrifugal Barrel Tumbling Work?

Centrifugal barrel finishing, also known as centrifugal barrel tumbling, operates on the “Ferris Wheel” principle with a one-to-one ratio of barrel rotation to turret rotation. The process involves loading four barrels with a mixture of parts, water, compound, and media, which are filled to around 50-80% capacity.

As the machine rotates, the barrels spin around the turret in a planetary motion, creating a sliding force inside the barrel. This motion generates high levels of friction and pressure between the abrasive media and parts and causes them to contact each other in random or isotropic directions. This results in an efficient process that removes burrs, polishes surfaces, and produces uniform finishes that are consistent across the entire part surface – also known as an isotropic finish.

Animation from DualSPHysics

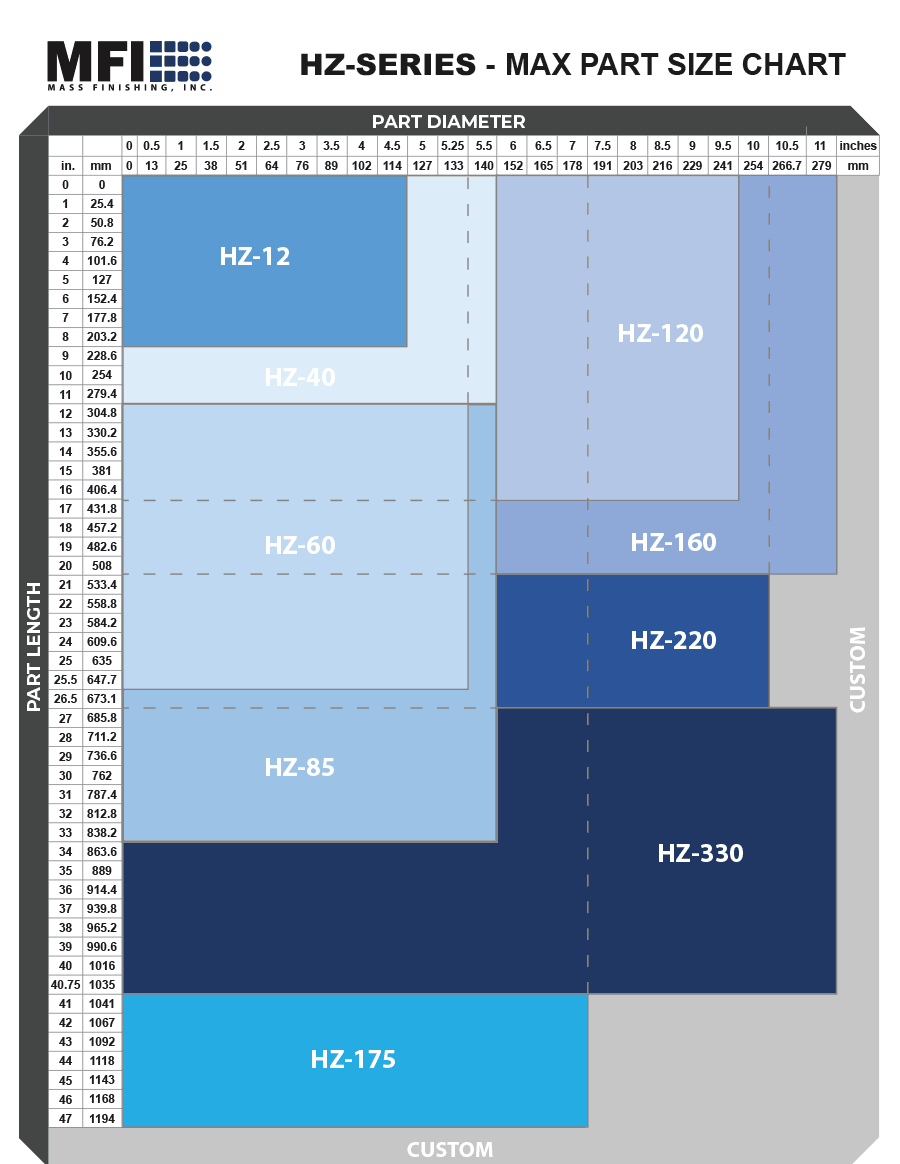

HZ-Series: Max Part Size Chart

By referencing this chart, you can easily identify the most suitable machine for your project. This visual tool identifies the maximum size of a part that can fit into our HZ-Series machines based on the part’s length and diameter.

You can always reach out to our team if you need assistance determining what model is right for your operation or production volume.

History of Centrifugal Barrel Tumbling or “Harperizing”

Harperizing was introduced to manufacturing in the 1960s by a company called Harper. For several decades the “Harperizer” became known mostly in the automotive industry for its ability to quickly remove excess materials from car parts in a short amount of time compared to traditional methods. Starting in the 1980s several companies around the world including Korea and Japan looked to replicate the technology and improve the ergonomics and safety of the machines. Mass Finishing machines are based on the Korean design and feature four barrels that revolve at a one-to-one ratio around a turret.

HZ-Series: Barrel Comparisons

Need Help Determining Your ROI?

We understand that your budget plays a significant role when making a purchase decision. To choose the right finishing equipment, we want your team to have all the information it needs. We can not only provide free sample parts processing but also calculate your expected ROI. If you are getting samples tested in our lab, please let a member of our team know you’re interested in receiving a cost analysis along with your confidential sample test report.