PV-.75 Vibratory Tub

Specs

PV-.75 Vibratory Tub

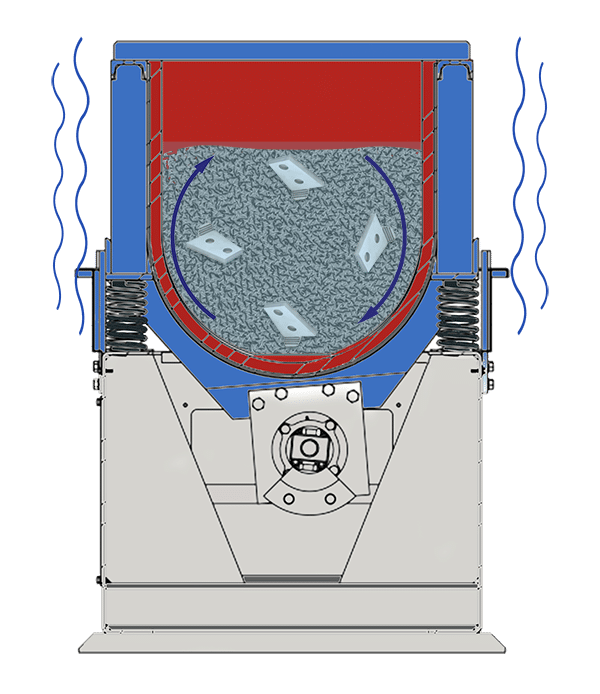

The PV-.75 vibratory tumbler is a compact and self-contained solution for fast and efficient deburring. These portable machines run extremely quiet and are a cost-effective solution to your deburring needs.

From coarse grinding to delicate polishing, the PV Series tumblers are suited for a wide variety of finishing applications. Deburring, descaling, polishing, cleaning and flash removal are all operations this series can effectively perform. Nearly all of your finishing needs are met with the use of standard media in the PV Series tumblers. However, when needed, MFI will provide a free technical analysis for your more specialized finish requirements.

Built for durability and years of dependable performance, the PV Series features a 14 gauge steel base that’s fully welded and enamel painted. It also includes cast-urethane-ribbed tub linings. Equipped with sound abatement features, the PV Series machines consistently maintain an operational noise level under 85 dBA.

These compact, self-contained vibratory tub systems fit into small spaces and the swivel castor wheels on the PV .75 and 2.5 allow for easy portability. Additionally, these machines typically operate on low voltage, resulting in lower electricity costs. Your PV Series machine will pay for itself in a very short time.

How It Works

From coarse grinding to delicate polishing, the PV Series tumblers are suited for a wide variety of finishing applications. Deburring, descaling, polishing, cleaning and flash removal are all operations this series can effectively perform. Utilizing a 2700 rpm vibratory eccentric shaft, the PV Series produces the same high-energy action as larger, more expensive vibrators.

Available Options and Accessories

Part and Media Separator

Processing Table and Sludge Tank

Media Drain Basket

Compound Auto-Flow System

Make the media and part separation process simple with our free standing media separator. Dump full barrels on the vibratory screen and watch as the media and your parts separate.

Reduce the mess from the process with MFI’s processing table and sludge tank. Sediment from your tumbling process is collected and easily cleaned out.

Fits into workstation sink and media separators. Screens in the bottom of the basket allow water to drain through so operator can pick out finished parts.

Hook up standard garden hose to unit to automatically feed water and chemical compounds into machine. Compound is drawn from bucket or drum below the unit.