Mass Finishing News

Employee Spotlight: Cole Mathisen

Cole started working on the Mass Finishing team in his early teens, when his father Mike and his uncle Tommy owned the company. He would mow the lawn, sweep the floors, and do other odd jobs around the facility. He worked at MFI during the summers through high school...

How to Use the Media Store

If your company has finishing or tumbling equipment, then you need media to make it all work right. MFI offers an incredibly wide variety of scientifically driven, lab-tested finishing media to suit virtually any surface finishing situation. If you have an MFI...

Employee Spotlight: Cory Carr

Cory Carr has worked on the Mass Finishing Inc. (MFI) team for nearly 8 years and is the Engineering Project/Production Manager. Cory originally started as the Engineering Project Manager and has since added “Production Manager” to his title. He has a AAS degree in...

Our Process: Free Sample Processing

An essential step in determining the right equipment for your part is running samples in our lab. Seeing is believing, so we offer sample processing at no cost to prove that we can give you the return on investment and quality finish you need to make your business...

New Rinse Screen Helping Customers

Rinse Screens have been a common topic of interest in many of our conversations lately with both existing and new customers. For those that may not be familiar with our Rinse Screen options for our HZ-Series Centrifugal Barrel Tumblers, we’d like to take the time to...

Equipment Spotlight: HZ-330 Product Video

In this week’s newsletter, we’re showcasing our HZ-330 Centrifugal Barrel Finisher. This model is the largest centrifugal barrel finisher that MFI offers, and it provides more than double the capacity and efficiency over the compact centrifugal barrel tumblers like...

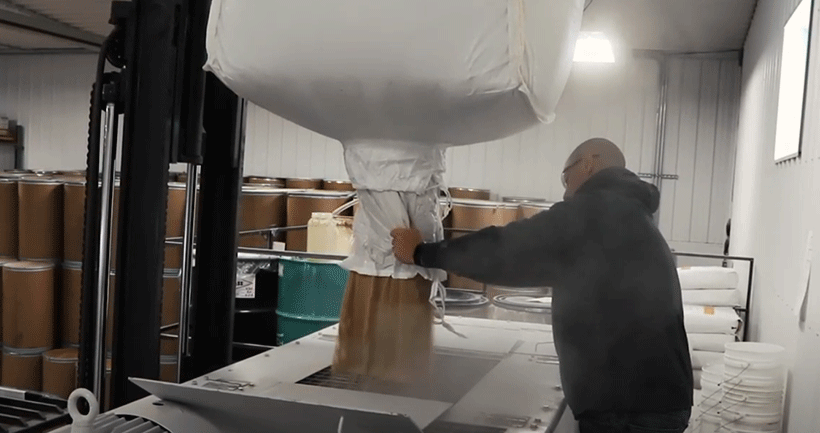

Mass Finishing Makes Ordering Corn Cob Blends Easier

Mass Finishing, Inc. is known for our high-quality dry finishing media options. In corn cob media alone, MFI sells over 250 tons each year. At our 10,000 square foot media storage and production facility, we add a variety of oils, micro-abrasives, and polishing agents...

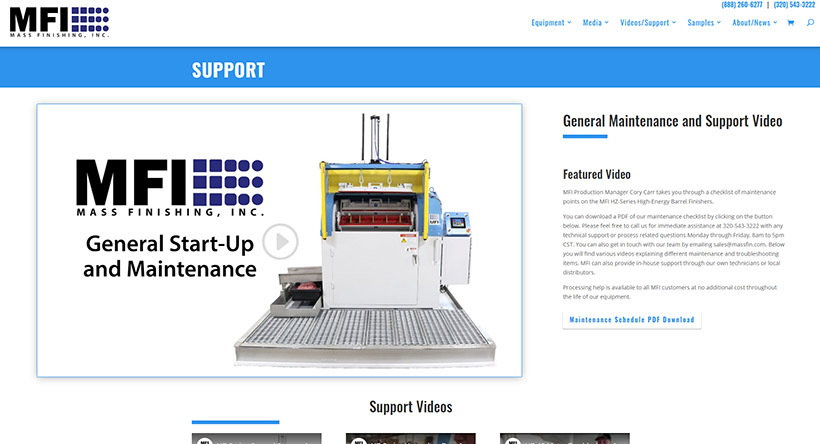

New Support Page and Video Demos for HZ-Series Maintenance

New to the MFI website is a Support page that gives customers extra resources and focuses on answering common questions customers have after the purchase of their HZ Series High Efficiency Barrell Tumbling Systems. On this new webpage you’ll find a variety of support...

How to Polish Gun Parts by Tumbling

Are you currently relying on handwork for deburring and polishing gun parts? The labor required to deburr and polish a single part is costly and time consuming. With demand for firearms at an all-time high, finding ways to streamline processes is important. Mass...

Equipment Spotlight: HZ-Series Rinse Screen Attachment

Save time and make life easier for operators by keeping media in barrel while rinsing. Howard Lake, MN – Creating better ergonomics and adding efficiency is a continuous process for Mass Finishing Inc. (MFI). With our HZ-Series Centrifugal Barrel Tumblers, anything we...

Cutting Tool Engineering Magazine’s Interview

Cutting Tool Engineering Magazine interviewed Cole Mathisen of Mass Finishing Inc. (MFI) as well as Ken Raby of Walther Trowal LLC, and Bernhard Kerschbaum of Rösler Group to discuss considerations for deburring and polishing and the benefits the right equipment can...

New Partnership Announcement with Mass Finishing Inc.

“We are always looking for ways to improve our processes and products,” commented Dan Keenan, Chief Technical Officer at Roush Yates Manufacturing Solutions. “The HZ Barrel Finisher will reduce our overall cycle time and produce a superior isotropic finished part.