Mass Finishing News

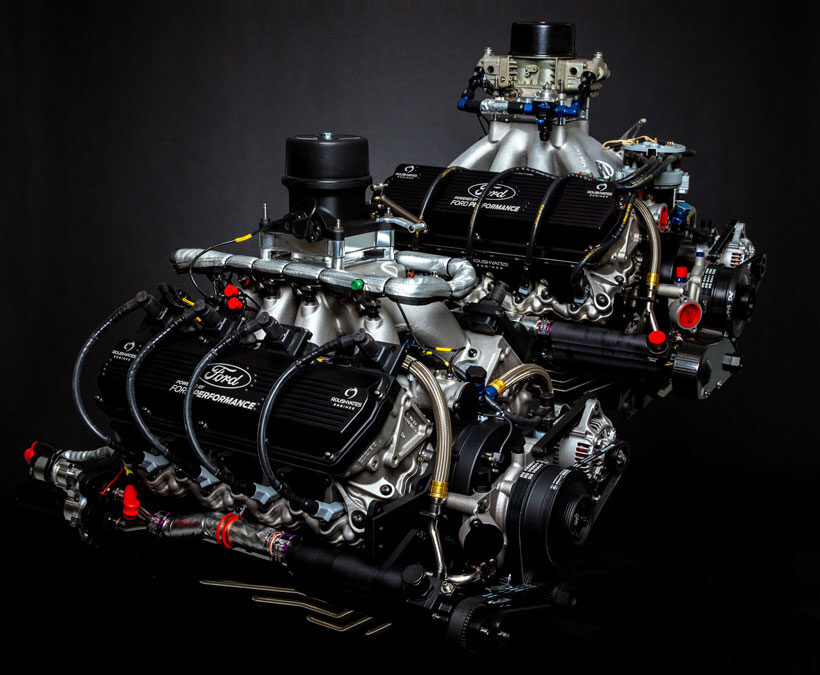

Mass Finishing, Inc. Partners with Roush Yates Engines

MFI Looks to Increase Brand Awareness with Performance Racing Partner Mass Finishing Inc. (MFI) is well known in the surface finishing world for their high-speed equipment. Now MFI is working with Roush Yates Engines, a high-speed partner. In August of 2020, Roush...

MFI Offering Centrifuge for Wastewater Cleaning

Finding a way to manage the wastewater generated during the tumbling process is a key aspect of any new finishing application. Mass Finishing customers around the world ask for help managing their waste stream and MFI now has a great product to help manage the issue....

MFI Tests Out New Pre-Polishing Media

Mass Finishing Lab Engineers are always working to come up with new processes to help improve the finish quality and performance of equipment. MFI regularly takes in new media from suppliers to test out in the lab. Our latest experiments include a Pre-Polishing...

MFI Feature in Modern Machine Shop

High-Energy Barrel Finishers Efficiently Deburr Complex Parts Mass Finishing Inc. has developed high-energy barrel finishers that automate the process of deburring complex parts, saving time and eliminating the need to deburr parts by hand. ELI PLASKETT Associate...

MFI Customer Support Around the World

In the last year, Mass Finishing has shipped machines to Turkey, South Africa, South America, Japan and Australia just to name a few. Recently we built a machine for the University of Auckland in New Zealand that took a six-week sea voyage to reach its destination....

The DeBertis Discover Barrel Polishing

The Twin Turbos found a turbo-charged way of polishing their billet aluminum car accessory parts. It’s increased speed and safety for their operation.

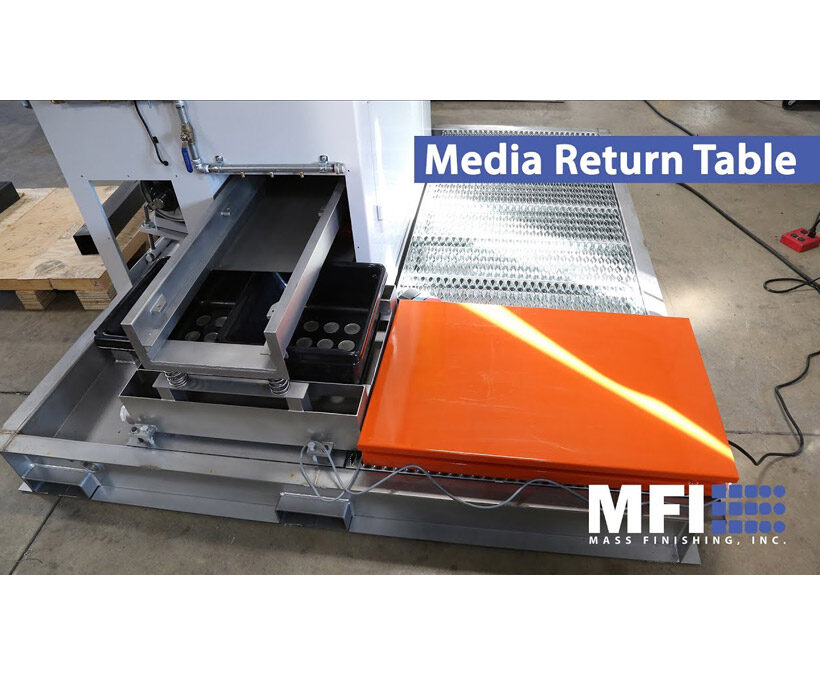

MFI Adds Media Lifting Table Option

Add Improved Ergonomics to Your Deburring and Polishing Operation MFI is constantly looking at ways to improve products through our own innovation or through feedback and suggestions from our customers. One of the key initiatives MFI is striving toward is eliminating...

MFI Adds Media Classification

DRASTICALLY REDUCE MEDIA LODGING ISSUES AND INCREASE PROCESS REPEATABILITY At Mass Finishing, we are constantly looking at ways we can improve our equipment and make it easier for operators to run. We do this through our lab technicians and through listening to...

Knife Deburring and Polishing Made Easy

Knife deburring and polishing is a hands free operation in high-energy centrifugal barrel tumblers. Some customers are saving 8 hours of finishing time.

Blanket Media Ordering Available

Did you know MFI takes blanket orders of media? For customers who want to make sure we have stock of their media, Mass Finishing accepts advanced orders on media. The term limit we offer is six months. Customers who use this method of supply order call MFI for...

Upcoming Tradeshows

2020 Mass Finishing Tradeshows: Rapid – Anaheim, CA April 20-23 Booth# 1033 American Association of Orthodontics – Atlanta, GA May 1-4 Booth# 221 IMTS – Chicago, IL September 14-19 Booth# 236945

Employee Spotlight: Ty Lehrke

Mass Finishing welcomes Ty Lehrke as a new Sales Person and Lab Engineer. Ty started at MFI on January 6, 2020 and he’s very excited to be a part of this great company! Ty’s been married to his wife Kristin for 22 years. They purchased Kristin’s childhood home about...