Surface Finishing for RAPID Manufacturing

Mass Finishing Inc. (MFI) provides finishing equipment to hundreds of customers in a variety of industries including customers in the additive manufacturing Industry. From 3D printed plastic to harder materials like titanium, MFI is experienced in improving surface roughness and achieving a high polish in minutes on additive components.

Additive manufacturing is quickly becoming a feasible option for full-scale manufacturing. However, the parts created using additive manufacturing processes are often left with very rough surfaces, scale, and other imperfections.

Using traditional hand polishing methods to improve these rough part surfaces is time-consuming and leads to costly labor expense. An operator can spend days to get the surfaces on a 3D printed part smoothed out by hand. For this reason, companies using this manufacturing process are often looking for an alternative solution for smoothing and polishing their parts that is quicker than hand polishing.

MFI’s HZ Series High Energy Centrifugal Barrel Finishing Machines can achieve an isotropic finish, meaning the parts are evenly finished in all directions and polish several parts at once. Our Centrifugal Barrel Finishing machines also help to eliminate handwork and will allow you to implement a finishing process that is efficient and repeatable.

3D Printed Parts

Achieving An Isotropic Finish with Centrifugal Barrel Tumbling

The HZ High Energy series Centrifugal Barrel Finishing (CBF) systems from Mass Finishing are the fastest and most economical form of finishing machine available. They are the industry workhorse in polishing, deburring and deflashing parts.

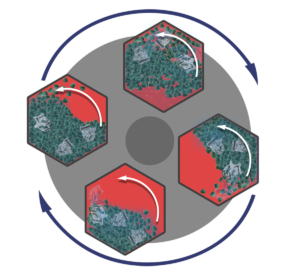

Ferris Wheel Principle

Centrifugal barrel finishing machines operate on the “Ferris Wheel” principle. Each of the four barrels is loaded to roughly 50-80% full of media, parts, water, and compound. During operation, the rotation causes parts and media to contact each other, resulting in a consistent isotropic finish across the entire surface of the part. An isotropic finish is a major advantage to using this more automated process, as an isotropic finish is not achievable by hand finishing.

In addition to creating an isotropic finish, our HZ High Energy Series equipment can remove large burrs from products in a matter of minutes, in what normally could take hours or even days by hand. It also smooths and prepares rough parts for anodizing.

Key Advantages to Barrel Tumbling

- Helps achieve an isotropic finish on parts

- Smooths out critical surfaces of precision parts

- Removes striation lines

- Breaks sharp edges

- Adds a mirror finish to highly sensitive parts

- Faster than hand-polishing

- Efficient and repeatable process

Speed – High Energy Barrel tumblers can tumble-finish parts in a fraction of the time when compared to vibratory or other traditional tumbling methods. In some cases, what could take four to eight hours in a vibratory machine is accomplished in 30 minutes or less through our centrifugal barrel tumblers.

No Part-on-Part Damage – The barrels or chambers on MFI machines are easily divided to create individual sections for each part. The dividers are easily moved to accommodate larger or smaller parts. With MFI Barrel Tumblers, the part only needs to fit in the chamber with room to tumble. There is no need to hold the part in place or fixture it to prevent damage.

Ability to Use Small Media – The force created when MFI centrifugal barrel tumblers are working at high-speed in upwards of 12 G force. This means even the tiniest media is able to work and rub against parts, accessing intricate pieces and features.

Free Parts Processing

If you have additive parts and are looking to decrease your processing time and achieve a high polish, you can send them to the MFI testing lab for free test processing.

Seeing is believing, so we offer sample processing at no cost to prove that we can give you the return on investment and quality finish you need to make your business successful.

An essential step in determining the right equipment, media, and production times for your part is running samples in our lab. Once we have your parts in house, we’ll determine what type of media and the processing times to get your desired finish. We’ll also provide before and after photos of your parts and a detailed lab report showing you the process time and details.

Let us show you what we can do with our HZ Series Centrifugal Barrel Finishers. Send MFI your parts today for free sample processing. We’ll turn around your parts in 3-5 days and send them back to you for review. It’s simple to get started, just submit this form and send your parts in.